They actually abolished the original legal requirement for those institutions to have free scholars as set out by their original charity school beginnings!!! WTF!

But the broadening of scope beyond the Church of England/medieval material was a good thing at least.

Like the special orthogonal group is to the orthogonal group, is the subset of with determinant equal to exactly 1.

Startup lists:

Deep tech (have labs) unicorns:

- Oxford Nanopore Technologies

- Graphcore

- CMR Surgical

- Britishvolt

- Touchlight Genetics

archean/proterozoic barrier.

The Neovius surface refers to a specific type of mathematical surface that has properties useful in the study of differential geometry and topology. It is named after the Finnish mathematician A.F. Neovius, who studied the surface and its properties. The Neovius surface is typically characterized by its complex structure, including features like cusps and self-intersections, making it interesting from the perspectives of both geometry and mathematical physics.

Supergeometry is a branch of mathematics that extends the concepts of geometry to include both geometric structures and "supersymmetrical" objects, which involve odd or "fermionic" dimensions. It arises from the study of supersymmetry in theoretical physics, where it plays a crucial role in string theory and quantum field theory. In conventional geometry, one typically works with spaces that are defined by traditional notions of points and curves in even-dimensional Euclidean spaces.

Pinned article: Introduction to the OurBigBook Project

Welcome to the OurBigBook Project! Our goal is to create the perfect publishing platform for STEM subjects, and get university-level students to write the best free STEM tutorials ever.

Everyone is welcome to create an account and play with the site: ourbigbook.com/go/register. We belive that students themselves can write amazing tutorials, but teachers are welcome too. You can write about anything you want, it doesn't have to be STEM or even educational. Silly test content is very welcome and you won't be penalized in any way. Just keep it legal!

Intro to OurBigBook

. Source. We have two killer features:

- topics: topics group articles by different users with the same title, e.g. here is the topic for the "Fundamental Theorem of Calculus" ourbigbook.com/go/topic/fundamental-theorem-of-calculusArticles of different users are sorted by upvote within each article page. This feature is a bit like:

- a Wikipedia where each user can have their own version of each article

- a Q&A website like Stack Overflow, where multiple people can give their views on a given topic, and the best ones are sorted by upvote. Except you don't need to wait for someone to ask first, and any topic goes, no matter how narrow or broad

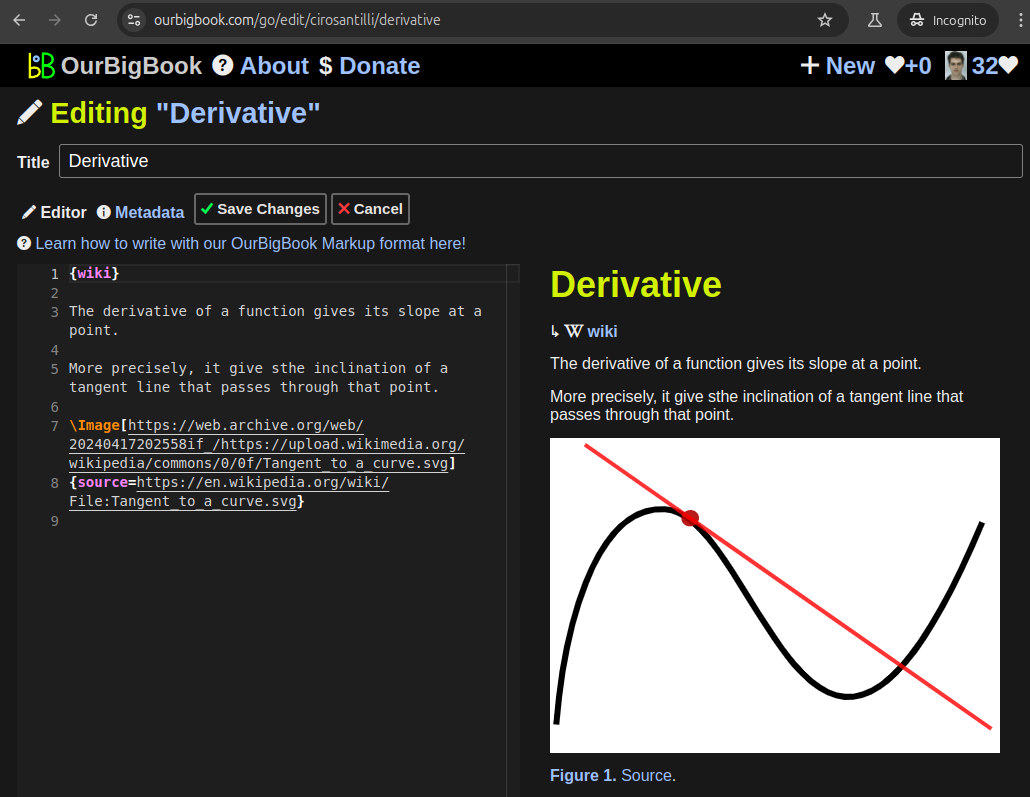

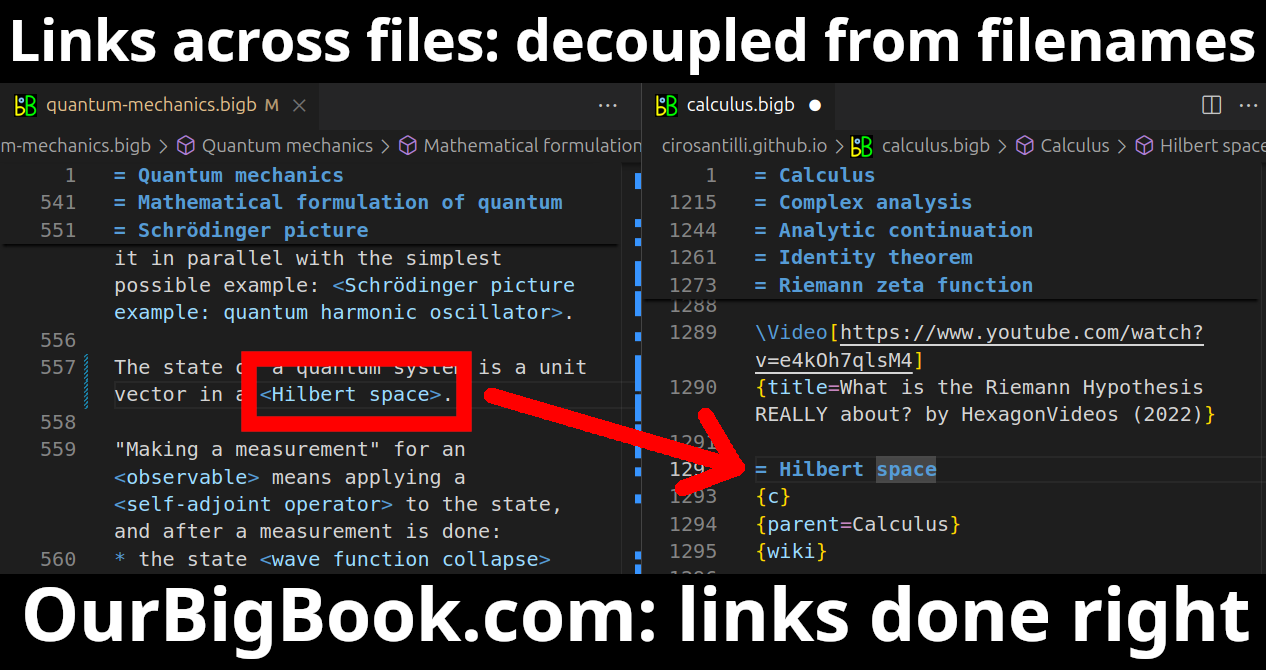

This feature makes it possible for readers to find better explanations of any topic created by other writers. And it allows writers to create an explanation in a place that readers might actually find it.Figure 1. Screenshot of the "Derivative" topic page. View it live at: ourbigbook.com/go/topic/derivativeVideo 2. OurBigBook Web topics demo. Source. - local editing: you can store all your personal knowledge base content locally in a plaintext markup format that can be edited locally and published either:This way you can be sure that even if OurBigBook.com were to go down one day (which we have no plans to do as it is quite cheap to host!), your content will still be perfectly readable as a static site.

- to OurBigBook.com to get awesome multi-user features like topics and likes

- as HTML files to a static website, which you can host yourself for free on many external providers like GitHub Pages, and remain in full control

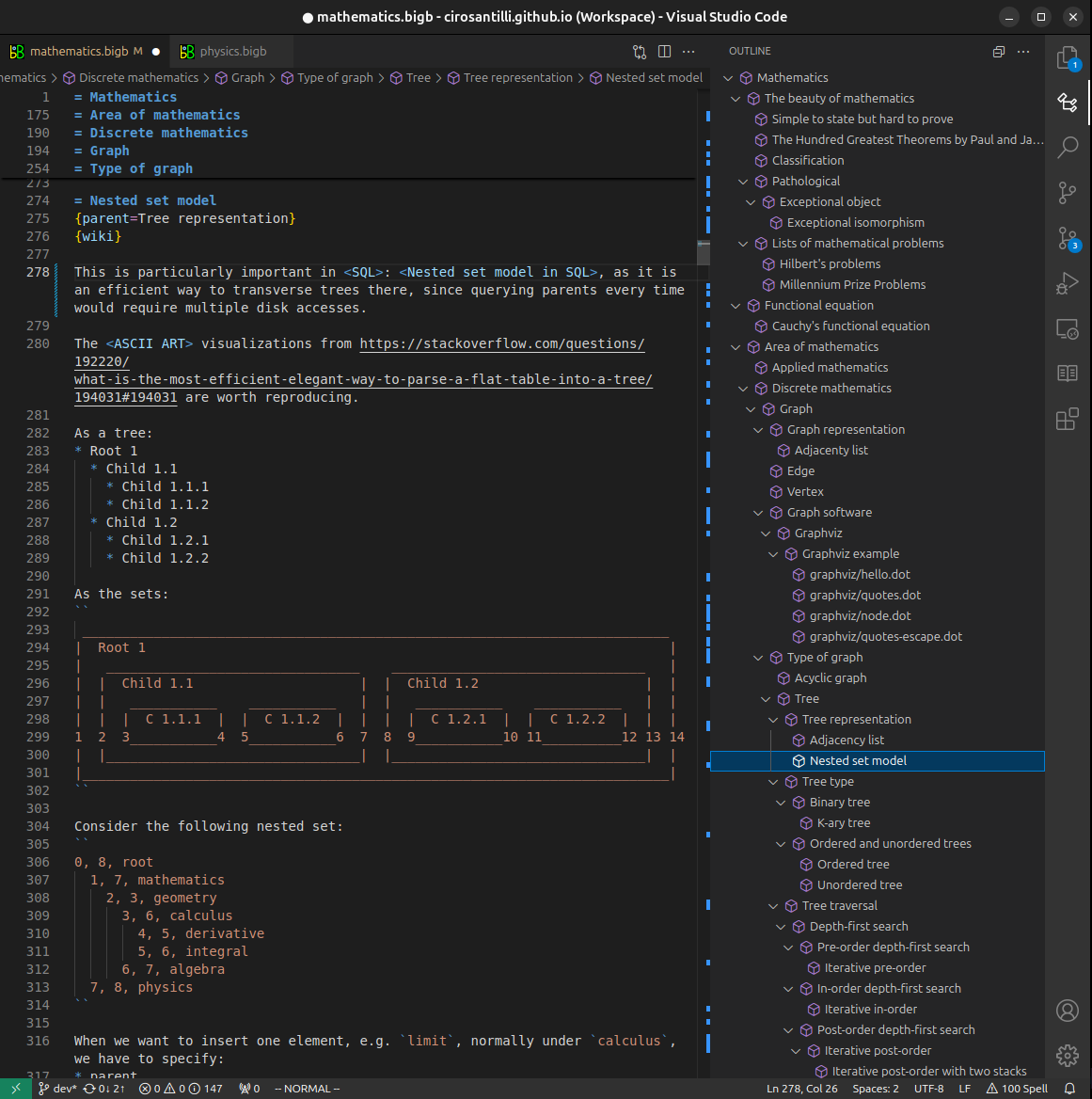

Figure 3. Visual Studio Code extension installation.Figure 4. Visual Studio Code extension tree navigation.Figure 5. Web editor. You can also edit articles on the Web editor without installing anything locally.Video 3. Edit locally and publish demo. Source. This shows editing OurBigBook Markup and publishing it using the Visual Studio Code extension.Video 4. OurBigBook Visual Studio Code extension editing and navigation demo. Source. - Infinitely deep tables of contents:

All our software is open source and hosted at: github.com/ourbigbook/ourbigbook

Further documentation can be found at: docs.ourbigbook.com

Feel free to reach our to us for any help or suggestions: docs.ourbigbook.com/#contact