Friction welding is a solid-state welding process that joins materials through the heat generated by mechanical friction between the workpieces, along with some applied pressure. Unlike traditional welding methods, which often involve melting the materials to create a joint, friction welding relies on the frictional heat produced at the interface of the materials being joined. ### Process Overview: 1. **Preparation**: The surfaces of the materials to be welded are typically cleaned and prepared to ensure a good bond.

Fusion welding is a process that involves the melting together of two or more pieces of material, typically metals, to create a strong bond as they cool and solidify. This technique relies on the application of heat to join the materials, and it is commonly used in various industries, including manufacturing, construction, and automotive.

Cold Metal Transfer (CMT) is a welding technology that is an advanced variation of gas metal arc welding (GMAW). CMT is characterized by its ability to produce low-heat, high-quality welds with minimal spatter and distortion. It is particularly effective for joining thin materials or materials that are sensitive to heat, such as aluminum and certain high-strength steels. The CMT process involves a unique interaction between the welding wire and the workpiece during the welding arc's operation.

Dissimilar friction stir welding (FSW) is a variant of traditional friction stir welding that involves joining two distinct materials, typically with different chemical compositions or physical properties, using a solid-state process. In standard friction stir welding, a rotating tool is used to generate frictional heat at the interface of two similar materials, which softens them and allows them to be forged together under pressure. In dissimilar FSW, the challenge lies in the different properties of the materials being joined.

Electric resistance welding (ERW) is a welding process that uses electrical resistance to generate heat for welding metal parts together. This type of welding is especially common for joining thin-walled materials and is often used in the fabrication of components in various industries, such as automotive, aerospace, and construction. ### Key Features of Electric Resistance Welding: 1. **Process**: In ERW, electrical current is passed through the workpieces to be welded.

The MS Carolinian is a passenger ferry that operates between South Carolina and North Carolina. Specifically, it primarily serves the route between the city of Cherry Grove, South Carolina, and the town of Hatteras, North Carolina. The ferry is an essential service for both residents and tourists, providing a means of transportation across the waters of the Pamlico Sound and allowing for easier access to various destinations along the Outer Banks.

Forming gas is a gas mixture that primarily consists of hydrogen and nitrogen, typically composed of about 95% hydrogen and 5% nitrogen. It is often used in various industrial applications, particularly in metalworking and welding processes. The main purposes of forming gas include: 1. **Reducing Agent**: Forming gas can serve as a reducing agent in reactions where metals are produced or processed, helping to prevent oxidation and improve the quality of the final product.

IR welding, or infrared welding, is a technique used to join materials, typically plastics, by utilizing infrared radiation to induce localized heating. This process involves the use of infrared heaters or sources that emit infrared energy, which is absorbed by the materials being welded. The heat generated causes the surface layers of the materials to soften or melt, allowing them to be fused together when pressure is applied.

Post Weld Heat Treatment (PWHT) is a process used in welding and metal fabrication to improve the mechanical properties of welded joints. It involves heating a welded assembly to a specific temperature and then allowing it to cool under controlled conditions. The primary purposes of PWHT include: 1. **Relieving Residual Stresses**: Welding can introduce internal stresses in the material due to thermal expansion and contraction. PWHT helps to reduce these residual stresses, which can lead to improved fatigue resistance and durability.

Radio-frequency welding, also known as RF welding or dielectric welding, is a manufacturing process used to join materials, typically thermoplastic materials, through the application of high-frequency electromagnetic energy. This technique utilizes radio waves to generate heat within the materials being joined, causing them to melt and fuse together at the interface. ### Key Features of Radio-frequency Welding: 1. **Principle of Operation**: The process involves placing the materials to be welded between two electrodes.

The heat-affected zone (HAZ) is a region in the base material of a workpiece that has been thermally impacted by welding, cutting, or other processes involving heat. While the material in the HAZ has not melted, it has been subjected to temperatures high enough to alter its microstructure and mechanical properties.

Welding documentation often includes a variety of symbols and conventions that communicate essential information about welding processes, specifications, and requirements. Understanding these symbols is crucial for ensuring proper interpretation and execution of welding tasks. Here are some key symbols and conventions commonly found in welding documentation: ### 1. **Welding Symbols**: - **Arrow and Reference Line**: The arrow points to the joint that will be welded, and the reference line is where the welding symbol is placed.

A "tailored blank" refers to a pre-formed piece of material that has been shaped or cut to precise specifications for a specific manufacturing process, such as stamping or forming. The term is commonly used in industries like automotive and aerospace, where components need to meet specific design and functionality criteria. In the context of metalworking, a tailored blank may involve techniques like laser cutting, shearing, or other processes to achieve the desired geometry before further processing like bending or welding.

Ultrasonic welding is a technique used to join two materials, usually thermoplastics or metal components, by applying high-frequency ultrasonic vibrations to produce localized melting at the interface of the materials. This process typically involves the following key elements: 1. **Ultrasonic Generator:** This device converts electrical energy into high-frequency ultrasonic vibrations, often in the range of 20 kHz to 40 kHz.

Linear vibration welding is a solid-state joining process used primarily for thermoplastic materials. This technique involves the use of high-frequency vibrations to create frictional heat at the interface between two parts, leading to their bonding without the need for additional adhesives or fasteners. ### Key Components of Linear Vibration Welding: 1. **Process Steps**: - **Alignment**: The parts to be welded are properly aligned.

Lyn Evans is a British physicist known for his work in the field of particle physics. He is particularly recognized for his role as the project leader of the Large Hadron Collider (LHC) at CERN (the European Organization for Nuclear Research), which is one of the most significant scientific endeavors in modern physics.

Edward Emerson Barnard (1857-1923) was an American astronomer and astrophotographer known for his significant contributions to the field of astronomy, particularly in the study of comets and the Milky Way. He is perhaps best known for discovering several comets, including Barnard's Comet (1889), and for his work in photographing the Milky Way, which provided valuable insights into its structure and composition.

Edwin Hubble was an American astronomer born on November 20, 1889, and he is best known for his groundbreaking contributions to the field of cosmology. His work fundamentally changed our understanding of the universe. Hubble is most famous for several key discoveries: 1. **Hubble's Law**: He established that the farther a galaxy is from Earth, the faster it appears to be moving away.

Oxy-fuel welding and cutting is a process that uses a flame produced by the combustion of a fuel gas, most commonly acetylene, and oxygen to weld and cut metals. This method is widely used in various industries for its versatility, simplicity, and effectiveness. ### Key Components: 1. **Fuel Gas**: The most common fuel gas used is acetylene, but other gases like propane, hydrogen, and natural gas can also be used.

Pattern welding is a traditional method of forging and shaping metal, particularly steel, that involves layering different types of iron and steel to create a distinctive, visually appealing pattern. This technique has historical significance and is most famously associated with the creation of beautiful and functional blades for weapons, such as swords and axes, particularly in the Viking Age and the production of Damascus steel. The process involves welding together multiple bars of ferrous metals with varying carbon content and properties.

Pinned article: ourbigbook/introduction-to-the-ourbigbook-project

Welcome to the OurBigBook Project! Our goal is to create the perfect publishing platform for STEM subjects, and get university-level students to write the best free STEM tutorials ever.

Everyone is welcome to create an account and play with the site: ourbigbook.com/go/register. We belive that students themselves can write amazing tutorials, but teachers are welcome too. You can write about anything you want, it doesn't have to be STEM or even educational. Silly test content is very welcome and you won't be penalized in any way. Just keep it legal!

Intro to OurBigBook

. Source. We have two killer features:

- topics: topics group articles by different users with the same title, e.g. here is the topic for the "Fundamental Theorem of Calculus" ourbigbook.com/go/topic/fundamental-theorem-of-calculusArticles of different users are sorted by upvote within each article page. This feature is a bit like:

- a Wikipedia where each user can have their own version of each article

- a Q&A website like Stack Overflow, where multiple people can give their views on a given topic, and the best ones are sorted by upvote. Except you don't need to wait for someone to ask first, and any topic goes, no matter how narrow or broad

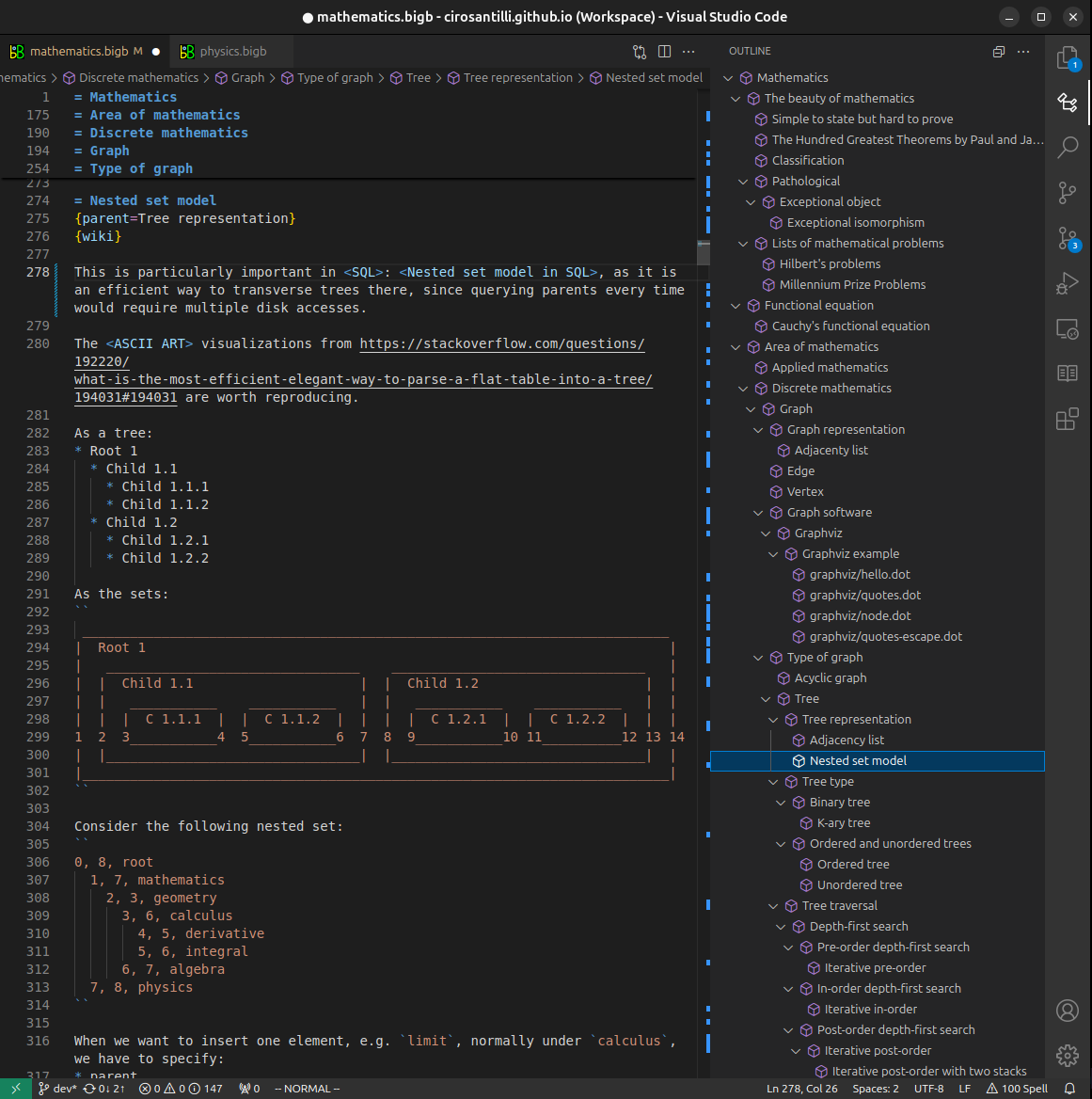

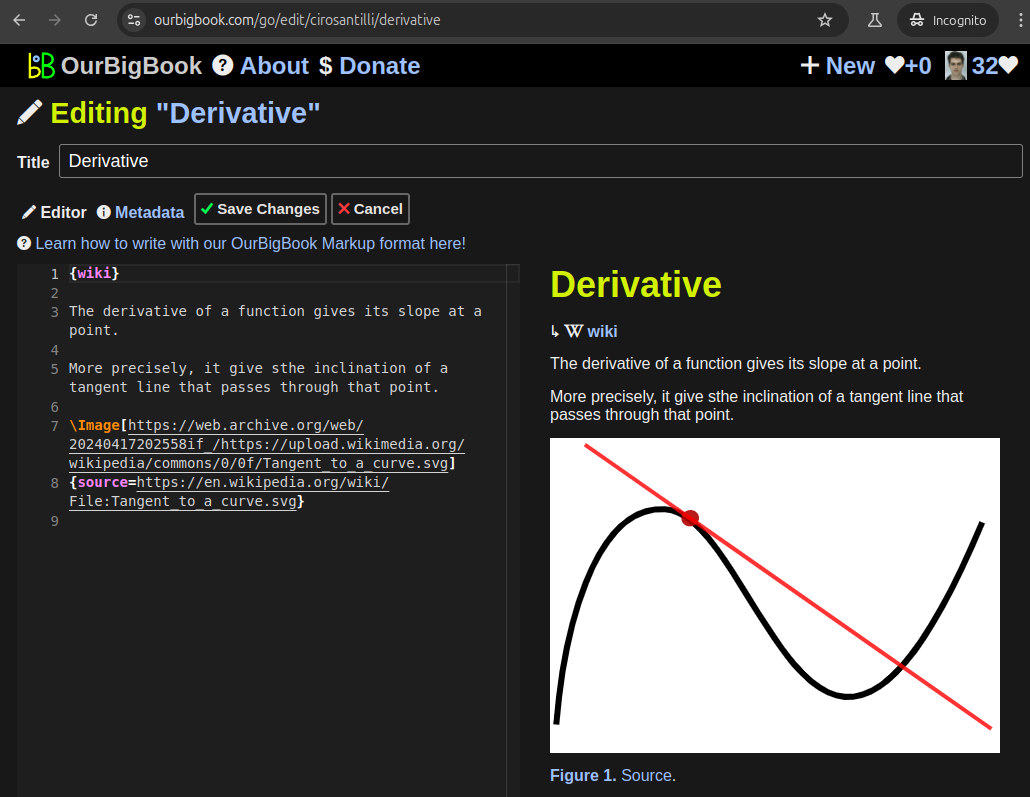

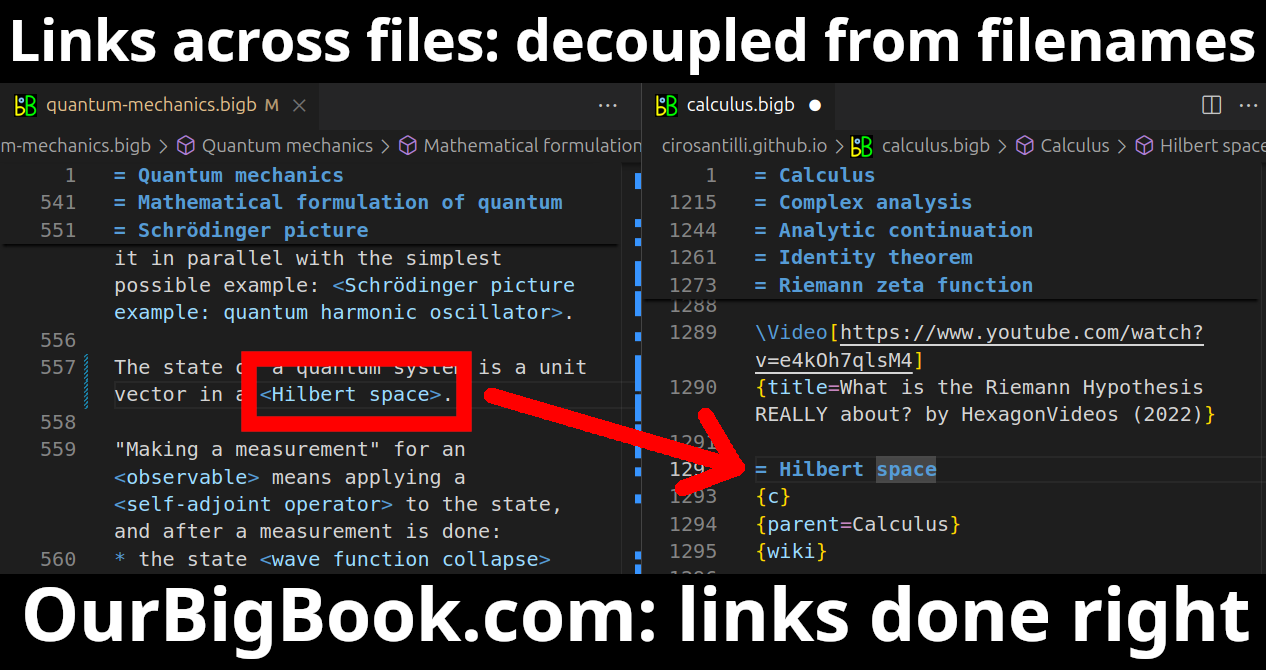

This feature makes it possible for readers to find better explanations of any topic created by other writers. And it allows writers to create an explanation in a place that readers might actually find it.Figure 1. Screenshot of the "Derivative" topic page. View it live at: ourbigbook.com/go/topic/derivativeVideo 2. OurBigBook Web topics demo. Source. - local editing: you can store all your personal knowledge base content locally in a plaintext markup format that can be edited locally and published either:This way you can be sure that even if OurBigBook.com were to go down one day (which we have no plans to do as it is quite cheap to host!), your content will still be perfectly readable as a static site.

- to OurBigBook.com to get awesome multi-user features like topics and likes

- as HTML files to a static website, which you can host yourself for free on many external providers like GitHub Pages, and remain in full control

Figure 2. You can publish local OurBigBook lightweight markup files to either OurBigBook.com or as a static website.Figure 3. Visual Studio Code extension installation.Figure 5. . You can also edit articles on the Web editor without installing anything locally. Video 3. Edit locally and publish demo. Source. This shows editing OurBigBook Markup and publishing it using the Visual Studio Code extension. - Infinitely deep tables of contents:

All our software is open source and hosted at: github.com/ourbigbook/ourbigbook

Further documentation can be found at: docs.ourbigbook.com

Feel free to reach our to us for any help or suggestions: docs.ourbigbook.com/#contact