Baroque music manuscript sources refer to the written documents that contain musical compositions from the Baroque period, roughly spanning from the late 16th century to the early 18th century (approximately 1600 to 1750). These manuscripts are crucial for the study and performance of Baroque music, as they provide early versions of works composed during this era, including those by prominent composers such as Johann Sebastian Bach, George Frideric Handel, Antonio Vivaldi, and Claudio Monteverdi.

Binary-Coded Decimal (BCD) is a binary encoding scheme used to represent decimal numbers in a format that is easy to read for both humans and computers. In BCD, each digit of a decimal number is represented by its own binary sequence. For example, the decimal number 43 would be encoded in BCD as follows: - The digit '4' is represented as 0100 in binary. - The digit '3' is represented as 0011 in binary.

A binary multiplier is a digital electronic circuit or algorithm that multiplies two binary numbers. It performs the multiplication of binary numbers, similar to how decimal multiplication is carried out, but it operates on binary digits (bits, which can be 0 or 1). ### Key Concepts: 1. **Binary Representation**: Numbers in binary are represented using two symbols (0 and 1). For example, the binary number `101` represents `5` in decimal.

Bitwise operations are operations that directly manipulate bits within binary representations of integers. These operations perform arithmetic and logical operations at the bit level, meaning they operate on the binary digits (0s and 1s) that compose the integer values.

Double Dabble is a technique commonly used in digital electronics and computer architecture, primarily for converting binary numbers (particularly binary-coded decimal, or BCD) into a format suitable for display, such as a seven-segment display. The Double Dabble algorithm involves several steps: 1. **Input Format**: It usually starts with input values represented in binary format. For BCD, each digit is encoded in four bits.

Quadruple-precision floating-point format is a computer number format that provides a very high level of precision for representing real numbers. It is part of the IEEE 754 standard, which specifies how floating-point numbers should be represented and manipulated in computing environments. Here are some key characteristics of quadruple-precision format: 1. **Bit Width**: Quadruple precision typically uses 128 bits (or 16 bytes) to store a single floating-point number.

Barry Pennington could refer to different things depending on the context, but without additional details, it's unclear which specific Barry Pennington you are inquiring about. 1. **Individual**: It could refer to a person named Barry Pennington, who may be known in a specific field such as sports, academia, or business. 2. **Fictional Character**: It could be a character from a book, movie, or TV show.

The Basic Limiting Principle is a concept in various fields, including economics, biology, and environmental science, referring to the idea that growth or production in a system is constrained by certain limiting factors. Essentially, it posits that no matter how favorable conditions may be, one or more resources or conditions will ultimately cap the level of growth or performance that can be achieved.

A **Happy Number** is defined as a number that eventually reaches 1 when replaced repeatedly by the sum of the squares of its digits. If it does not reach 1, it will enter a cycle that does not include 1, and it is then considered an unhappy number. The process for determining if a number is happy can be described as follows: 1. Take the number and replace it with the sum of the squares of its digits. 2. Repeat this process.

Bayesian networks, also known as belief networks or Bayes nets, are a type of graphical model that represent a set of variables and their conditional dependencies using a directed acyclic graph (DAG). In a Bayesian network: 1. **Nodes** represent random variables, which can be discrete or continuous. 2. **Directed Edges** indicate causal relationships or dependencies between the variables. An edge from node A to node B suggests that A has some influence on B.

A subtractor is a digital circuit that performs subtraction on binary numbers. It is commonly used in arithmetic logic units (ALUs) and various computing applications. The simplest form of a subtractor is a **half subtractor**, which takes two input bits and produces a difference and a borrow output. A more complex version is the **full subtractor**, which handles borrowing from previous bits, allowing it to subtract multi-bit binary numbers.

Levi's lemma, also known as the Lebesgue’s dominated convergence theorem, is a result in the theory of integration, specifically concerning the conditions under which one can interchange limits and integrals.

ENO methods, or Essentially Non-Oscillatory methods, are a class of numerical techniques used primarily for the solution of hyperbolic partial differential equations (PDEs). They are particularly valuable for problems where shock waves or discontinuities are present, as they help prevent artificial oscillations that can occur in traditional numerical methods.

A simplicial sphere is a type of topological space that arises in the field of algebraic topology and combinatorial geometry. More specifically, it is a simplicial complex that is homeomorphic to a sphere. ### Definition A **simplicial complex** is a set of simplices that satisfies certain conditions, such as closure under taking faces and the intersection property.

Garnir relations refer to a specific set of algebraic identities that arise in the context of representation theory and the study of certain mathematical structures, particularly in relation to symmetric groups and permutation representations. Named after the mathematician Jean Garnir, these relations are particularly important in the study of the modular representation theory of symmetric groups and their related structures.

Partially solved games are games for which some knowledge about optimal strategies exists, but the game has not been completely solved. This means that while certain positions or states of the game may have been analyzed to the point of determining the best moves or strategies, not every possible position has been explored exhaustively.

Positional games are a type of combinatorial game that involve two players competing to control positions or resources on a board or in a structured environment. These games are often defined by specific rules regarding how players can make moves and how they can claim or occupy spaces. In a typical positional game, players take turns making moves that affect the game state, with the primary objective of achieving a particular configuration or control over the board.

Pinned article: Introduction to the OurBigBook Project

Welcome to the OurBigBook Project! Our goal is to create the perfect publishing platform for STEM subjects, and get university-level students to write the best free STEM tutorials ever.

Everyone is welcome to create an account and play with the site: ourbigbook.com/go/register. We belive that students themselves can write amazing tutorials, but teachers are welcome too. You can write about anything you want, it doesn't have to be STEM or even educational. Silly test content is very welcome and you won't be penalized in any way. Just keep it legal!

Intro to OurBigBook

. Source. We have two killer features:

- topics: topics group articles by different users with the same title, e.g. here is the topic for the "Fundamental Theorem of Calculus" ourbigbook.com/go/topic/fundamental-theorem-of-calculusArticles of different users are sorted by upvote within each article page. This feature is a bit like:

- a Wikipedia where each user can have their own version of each article

- a Q&A website like Stack Overflow, where multiple people can give their views on a given topic, and the best ones are sorted by upvote. Except you don't need to wait for someone to ask first, and any topic goes, no matter how narrow or broad

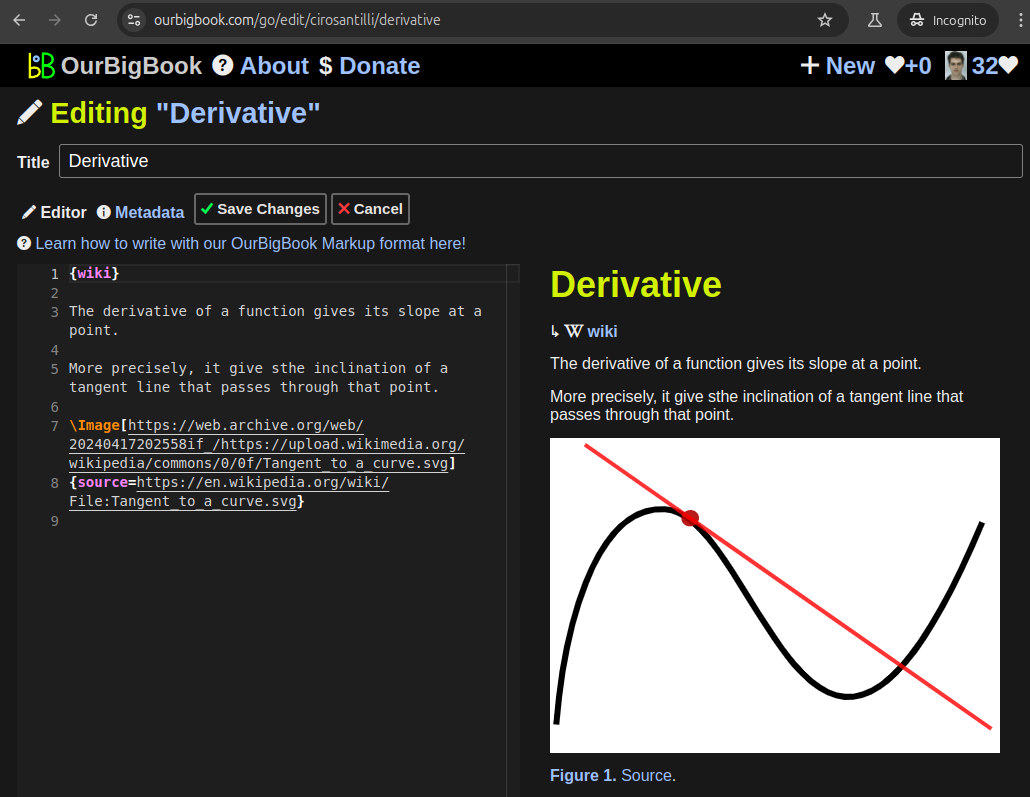

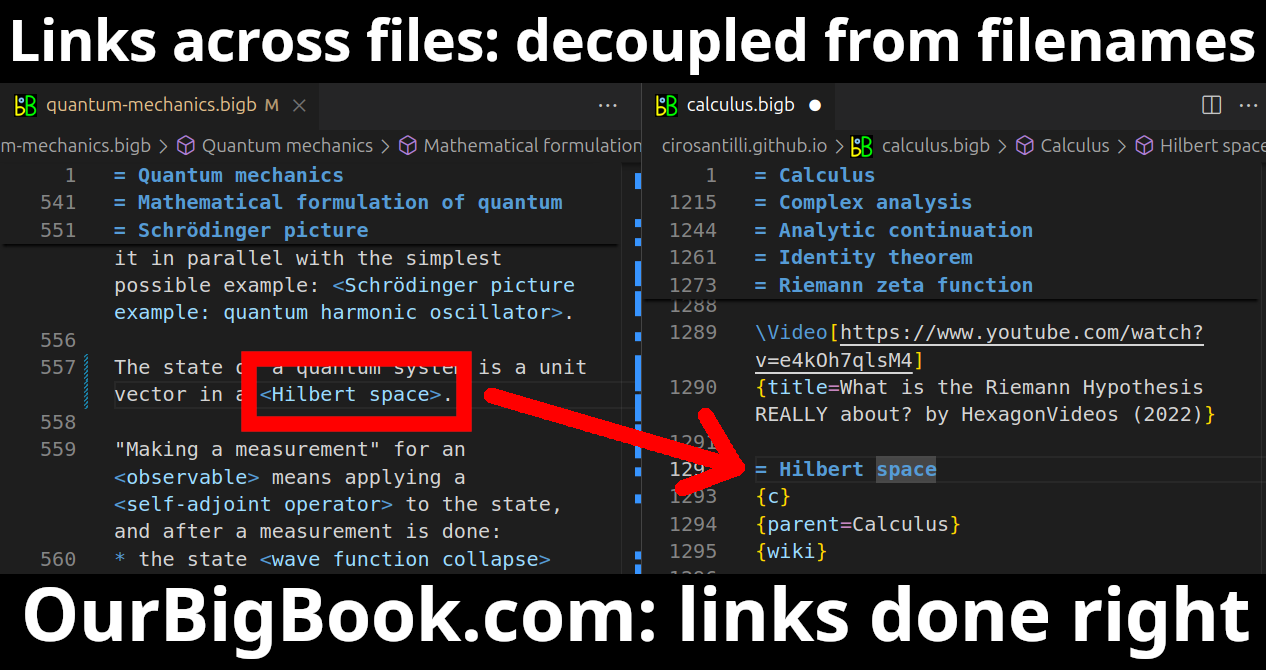

This feature makes it possible for readers to find better explanations of any topic created by other writers. And it allows writers to create an explanation in a place that readers might actually find it.Figure 1. Screenshot of the "Derivative" topic page. View it live at: ourbigbook.com/go/topic/derivativeVideo 2. OurBigBook Web topics demo. Source. - local editing: you can store all your personal knowledge base content locally in a plaintext markup format that can be edited locally and published either:This way you can be sure that even if OurBigBook.com were to go down one day (which we have no plans to do as it is quite cheap to host!), your content will still be perfectly readable as a static site.

- to OurBigBook.com to get awesome multi-user features like topics and likes

- as HTML files to a static website, which you can host yourself for free on many external providers like GitHub Pages, and remain in full control

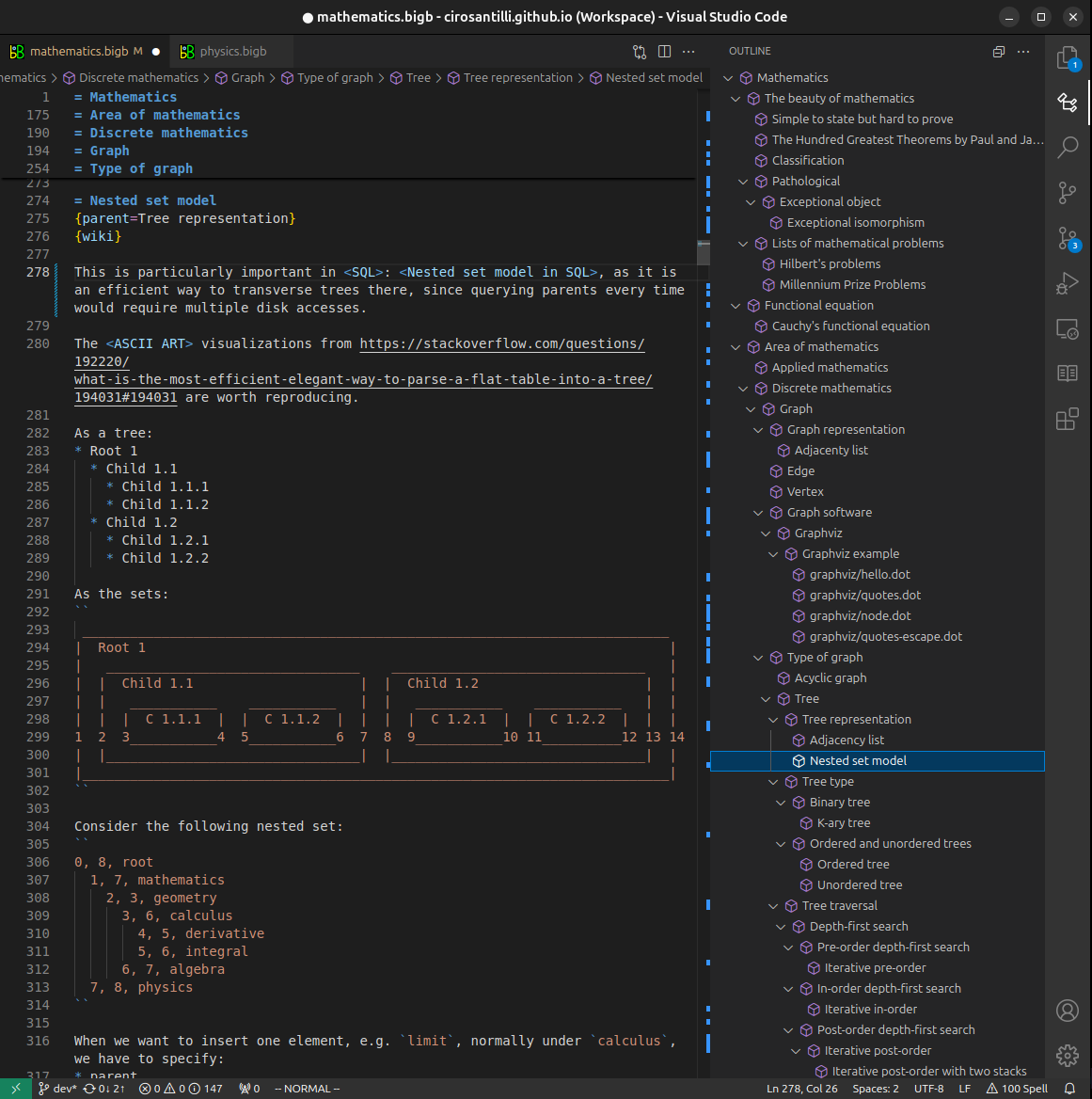

Figure 3. Visual Studio Code extension installation.Figure 4. Visual Studio Code extension tree navigation.Figure 5. Web editor. You can also edit articles on the Web editor without installing anything locally.Video 3. Edit locally and publish demo. Source. This shows editing OurBigBook Markup and publishing it using the Visual Studio Code extension.Video 4. OurBigBook Visual Studio Code extension editing and navigation demo. Source. - Infinitely deep tables of contents:

All our software is open source and hosted at: github.com/ourbigbook/ourbigbook

Further documentation can be found at: docs.ourbigbook.com

Feel free to reach our to us for any help or suggestions: docs.ourbigbook.com/#contact