Mokume-gane is a traditional Japanese metalworking process that creates a layered metal pattern, resembling wood grain. The term "mokume-gane" translates to "wood eye metal," which reflects the visual resemblance to wood textures. This technique was originally developed in the 17th century by Japanese samurai sword makers, who sought to create aesthetically pleasing and durable blades. The process involves layering different types of metals, typically including precious metals like gold, silver, and copper.

Openwork refers to a collaborative and transparent approach in various fields, including finance, design, and software development, where multiple parties can contribute and interact in an open environment. The term can also relate to specific organizational structures or frameworks that emphasize community engagement, open communication, or shared resources. In a financial context, Openwork is a UK-based network that connects financial advisers with access to a range of financial products and services. It aims to support its members in providing independent financial advice to clients.

Peening is a mechanical process used to improve the properties of materials, primarily metals, through the application of a mechanical impact, which induces compressive stresses on the material's surface. This process enhances the material's fatigue resistance, increases hardness, and can help prevent cracking.

Metamaterial cloaking is a concept rooted in the use of metamaterials—synthetic materials engineered to have properties not typically found in nature. These materials can manipulate electromagnetic waves in unconventional ways, enabling applications such as cloaking, which aims to render objects invisible or less detectable to specific types of waves, such as light or radar. The principle behind metamaterial cloaking involves bending waves around an object, so that the waves continue on their original path, effectively hiding the object from detection.

Press hardening, also known as hot stamping or hot forming, is a manufacturing process used primarily in the automotive and aerospace industries to create high-strength components from steel. This method involves the following steps: 1. **Heating**: A sheet of steel is heated to a high temperature (typically around 900°C) to become malleable. 2. **Forming**: The heated steel is then transferred to a press where it is shaped into the desired component using a die.

Primer is a type of paint that is used as a preparatory coat applied to surfaces before painting with the final or topcoat. The primary functions of primer include: 1. **Improving Adhesion**: Primer helps paint adhere better to the surface, preventing peeling or chipping over time. 2. **Sealing the Surface**: It can seal porous surfaces (like wood or drywall), preventing the topcoat from being absorbed unevenly. This results in a more uniform finish.

A V-block, also known as a V-block clamp or V-block fixture, is a tool used primarily in machine shops and laboratories for holding cylindrical objects securely during machining, measuring, or inspection processes. It typically has a V-shaped groove that allows round workpieces, such as shafts, rods, or tubes, to sit firmly in place, preventing them from rolling or shifting.

Vapor degreasing is a cleaning process that uses vaporized solvents to remove grease, oil, and other contaminants from metal parts and components. This method is particularly effective for precision cleaning applications, such as in the aerospace, automotive, and electronics industries, where even minimal residual contamination can affect performance. ### Key Features of Vapor Degreasing: 1. **Solvent Use**: The process typically employs halogenated solvents or other specialized cleaning solvents that vaporize easily.

A "Rust converter" typically refers to a tool or software that helps in converting code written in other programming languages to Rust, or it can be a library or utility that helps in managing and transforming Rust code itself. Here are a couple of interpretations of what a Rust converter might entail: 1. **Code Conversion Tool**: Some tools can take code written in languages like C or C++ and attempt to translate it into Rust.

San mai is a traditional Japanese method of sword-making that involves the layering of different types of steel to create a blade that combines the best properties of the materials used. The term "san mai" translates to "three layers" in Japanese, referring to the structure of the blade, which typically consists of a hard, high-carbon steel core sandwiched between two layers of softer, more ductile steel.

Vibratory finishing is a technique used in surface finishing processes to enhance the texture, smoothness, and overall appearance of a workpiece. This method utilizes a vibratory mass finishing machine that contains a bowl or tub filled with abrasive media (such as ceramic, plastic, or metal components) alongside the parts to be finished. Here's how it typically works: 1. **Vibration**: The machine generates vibrations that cause the media and parts to move in a controlled manner.

Nanolattices are advanced materials structured at the nanoscale, typically consisting of interconnected networks of nanoscale beams or struts. These three-dimensional architectures combine unique mechanical, thermal, and electrical properties due to their finely tuned porosity and geometry. Key characteristics and applications of nanolattices include: 1. **Lightweight and Strong**: Due to their intricate design, nanolattices can maintain structural integrity while being much lighter than traditional materials.

Shock hardening refers to a process in which materials, often metals, are subjected to high strain rates or impact loading that results in an increase in their hardness and strength. This occurs due to the rapid deformation mechanisms activated under such conditions, which can lead to a variety of microstructural changes in the material. Key aspects of shock hardening include: 1. **Strain Rate**: The high strain rates involved in shock hardening differ significantly from conventional deformation processes.

Sintering is a manufacturing process used to create solid materials from powders through the application of heat and (often) pressure. The main objectives of sintering are to increase the density and strength of the material by promoting particle bonding, which occurs without melting the primary constituent materials. ### Key Features of Sintering: 1. **Process Steps**: - **Powder Preparation**: Fine particles are prepared, often through milling or other methods to achieve the desired particle size and characteristics.

Skiving is a metalworking process used to achieve precise dimensions and a smooth finish on the outer or inner surfaces of a workpiece. It involves the removal of material through a cutting action, typically using a specifically designed tool or machine called a skiving tool or skiving machine. In skiving, the tool's cutting edge is presented to the workpiece at a slight angle, allowing it to shave or slice off thin layers of material.

A slitting mill is a type of machinery used in the metalworking industry to cut large rolls of material, often flat metal sheets or strips, into narrower strips or coils. The process is known as slitting, and it typically involves feeding the metal strip through a series of rotating blades or knives that create multiple narrower strips from the wider material. Slitting mills are commonly used in steel and aluminum processing, allowing for efficient production of various products such as metal roofing, electrical components, and automotive parts.

Slotted angle refers to a type of structural steel section commonly used in construction and manufacturing. It is characterized by its L-shaped profile with a series of slots or holes along its length. These slots allow for easy fastening and adjustment of components, making slotted angles versatile and useful in a variety of applications. Key features and uses of slotted angles include: 1. **Material Composition**: Typically made from mild steel or galvanized steel, slotted angles are strong and durable.

Solvent degreasing is a cleaning process that involves the use of chemical solvents to remove grease, oil, dirt, and other contaminants from various surfaces, particularly in industrial and manufacturing settings. This method is commonly applied to metal parts and components, where the removal of residues is necessary for further processing, assembly, or finishing.

Squeeze casting, also known as pressure casting, is a metal casting process that combines features of both casting and forging. This technique is used to produce highly dense metal parts with improved mechanical properties compared to those made through traditional casting methods. The process involves the following steps: 1. **Mold Preparation**: A mold is designed and prepared, typically made from materials such as steel to withstand high pressures and temperatures.

Steel wool is a type of abrasive material made from fine strands of steel that are twisted together. It is commonly used for scrubbing and cleaning purposes, as well as for polishing surfaces and finishing wood. Steel wool is available in various grades, ranging from coarse to fine, which indicates the thickness of the strands and the abrasiveness of the material.

Pinned article: Introduction to the OurBigBook Project

Welcome to the OurBigBook Project! Our goal is to create the perfect publishing platform for STEM subjects, and get university-level students to write the best free STEM tutorials ever.

Everyone is welcome to create an account and play with the site: ourbigbook.com/go/register. We belive that students themselves can write amazing tutorials, but teachers are welcome too. You can write about anything you want, it doesn't have to be STEM or even educational. Silly test content is very welcome and you won't be penalized in any way. Just keep it legal!

Intro to OurBigBook

. Source. We have two killer features:

- topics: topics group articles by different users with the same title, e.g. here is the topic for the "Fundamental Theorem of Calculus" ourbigbook.com/go/topic/fundamental-theorem-of-calculusArticles of different users are sorted by upvote within each article page. This feature is a bit like:

- a Wikipedia where each user can have their own version of each article

- a Q&A website like Stack Overflow, where multiple people can give their views on a given topic, and the best ones are sorted by upvote. Except you don't need to wait for someone to ask first, and any topic goes, no matter how narrow or broad

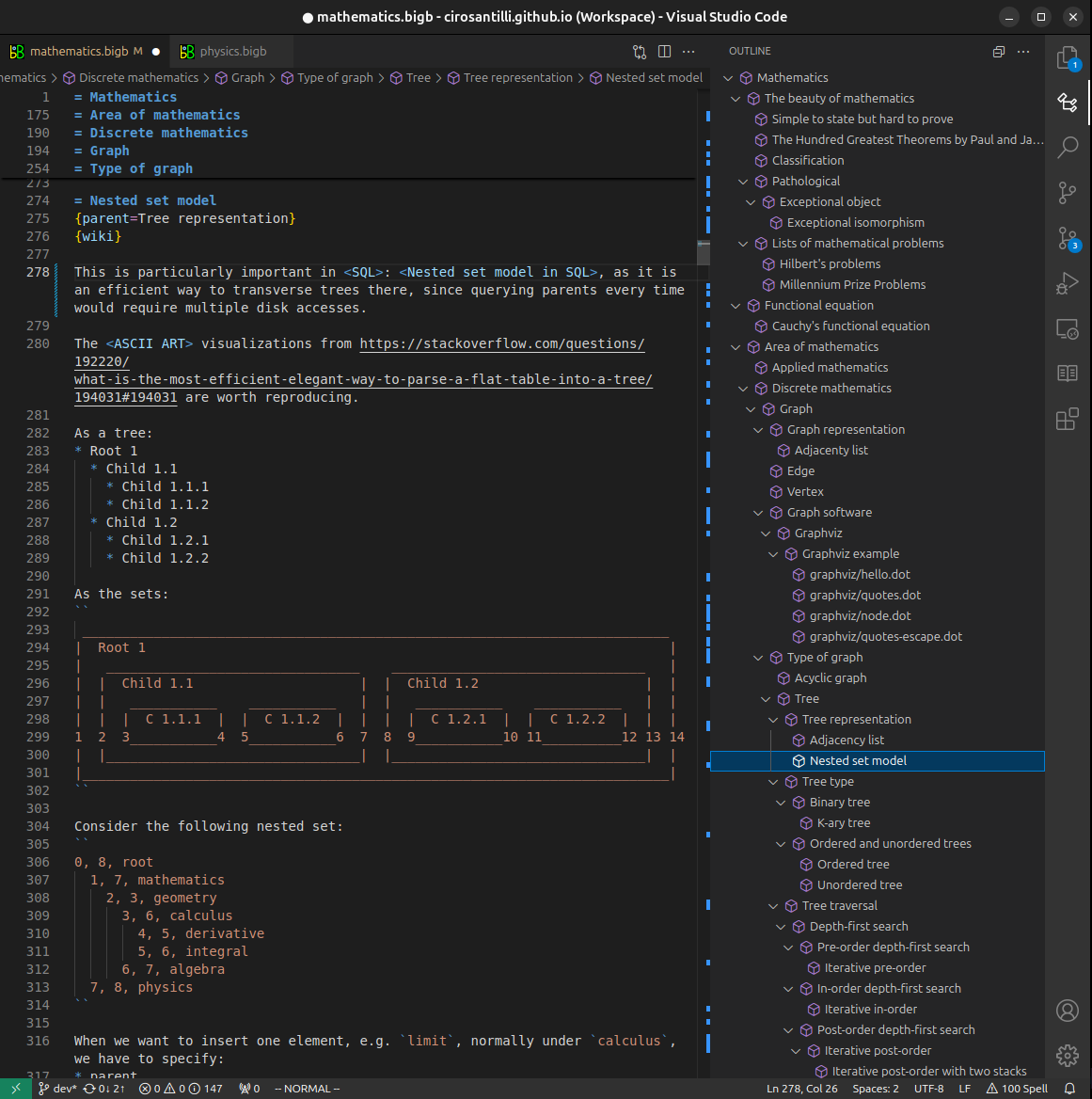

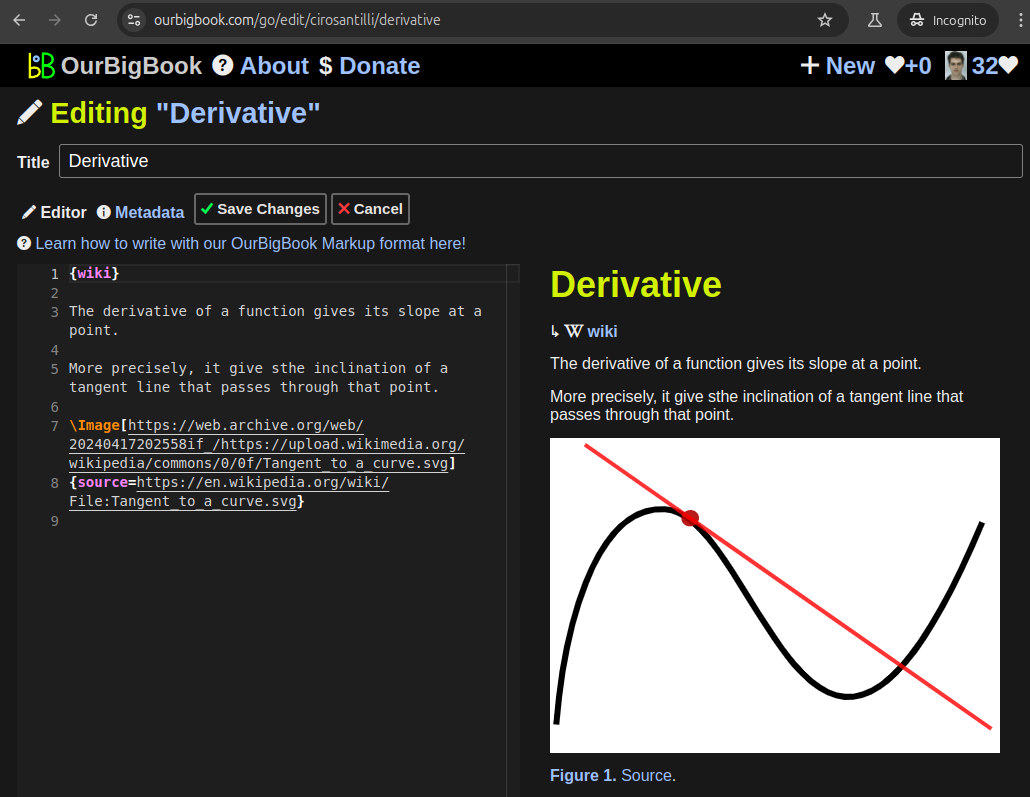

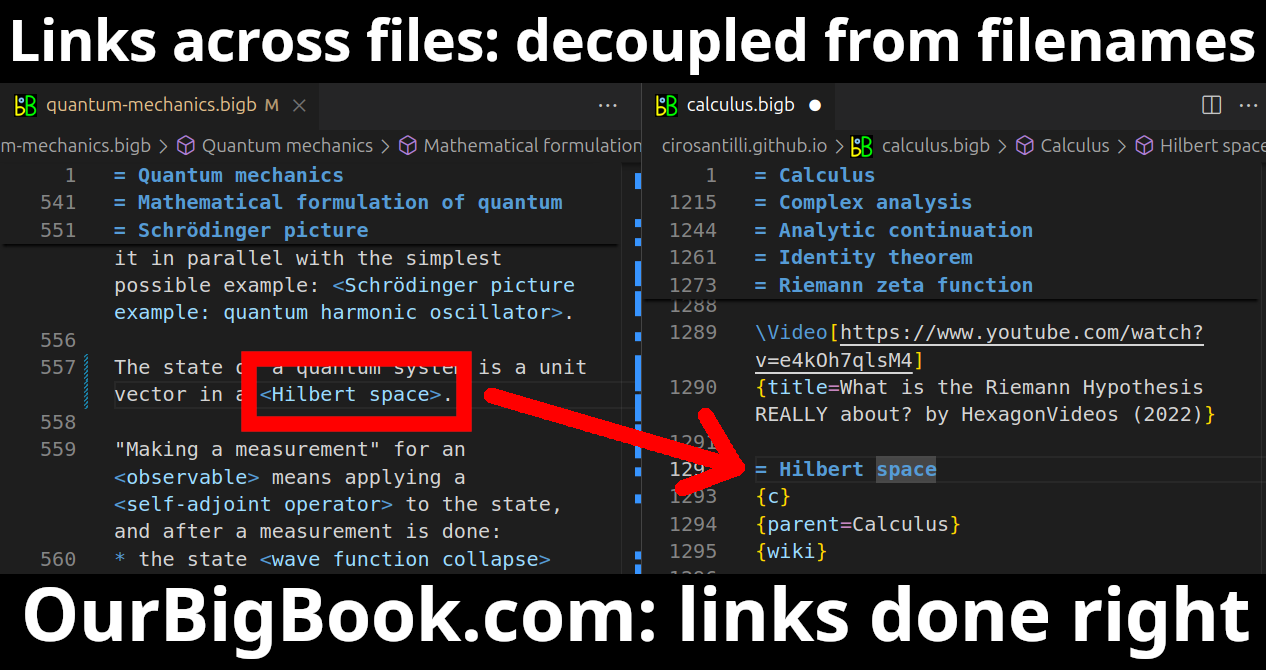

This feature makes it possible for readers to find better explanations of any topic created by other writers. And it allows writers to create an explanation in a place that readers might actually find it.Figure 1. Screenshot of the "Derivative" topic page. View it live at: ourbigbook.com/go/topic/derivativeVideo 2. OurBigBook Web topics demo. Source. - local editing: you can store all your personal knowledge base content locally in a plaintext markup format that can be edited locally and published either:This way you can be sure that even if OurBigBook.com were to go down one day (which we have no plans to do as it is quite cheap to host!), your content will still be perfectly readable as a static site.

- to OurBigBook.com to get awesome multi-user features like topics and likes

- as HTML files to a static website, which you can host yourself for free on many external providers like GitHub Pages, and remain in full control

Figure 2. You can publish local OurBigBook lightweight markup files to either OurBigBook.com or as a static website.Figure 3. Visual Studio Code extension installation.Figure 5. . You can also edit articles on the Web editor without installing anything locally. Video 3. Edit locally and publish demo. Source. This shows editing OurBigBook Markup and publishing it using the Visual Studio Code extension. - Infinitely deep tables of contents:

All our software is open source and hosted at: github.com/ourbigbook/ourbigbook

Further documentation can be found at: docs.ourbigbook.com

Feel free to reach our to us for any help or suggestions: docs.ourbigbook.com/#contact