Spacetime algebra is a mathematical framework that combines concepts from geometry and algebra to describe the structure of spacetime in the context of physics, particularly in the realm of special relativity. It is built on the foundations of Clifford algebra, a type of algebra that generalizes the notion of vectors and includes notions of angles, distances, and rotations.

The Spanish Data Protection Agency (Agencia Española de Protección de Datos, AEPD) is the national authority responsible for overseeing and enforcing data protection laws in Spain. Established in 1992, the AEPD is tasked with ensuring compliance with the General Data Protection Regulation (GDPR) and other relevant data protection laws, both at the national and European levels.

Spatial scale refers to the physical dimensions or extent of a geographic area being studied or analyzed. It is a critical concept in various fields, including geography, ecology, urban planning, and remote sensing, as it influences the patterns and processes observed in spatial data. Spatial scale can be characterized in several ways: 1. **Map Scale**: This refers to the ratio of a distance on a map to the corresponding distance on the ground. A small-scale map shows a larger area with less detail (e.

Spenta R. Wadia is a prominent Indian theoretical physicist known for his contributions to the field of condensed matter physics, particularly in the areas of quantum materials and topological phases of matter. He is associated with research institutions in India and has published numerous papers on topics like quantum entanglement, electronic properties of materials, and the theoretical understanding of complex systems. His work often intersects with interdisciplinary fields, linking physics with materials science and engineering.

A spherical code is a mathematical concept that deals with arrangements of points on the surface of a sphere. In particular, spherical codes are used to study the optimal placement of points in order to maximize the minimum distance between them, given certain constraints. The study of spherical codes has various applications in areas such as telecommunications, error correction, and sensor networks, among others.

The spheroidal wave equation is a second-order partial differential equation that arises in various physical contexts, particularly in problems involving spherical and spheroidal symmetry, such as acoustics, quantum mechanics, and electromagnetic theory. It describes the behavior of wave functions in spheroidal coordinates, which are related to both spherical and cylindrical coordinates.

A spit is a coastal landform formed by the deposition of sediment, typically sand or gravel, which extends from the shoreline into a body of water. It is usually created by the action of longshore drift, where waves and currents transport sediment along the coast. Spits can vary in size and shape, often appearing as narrow stretches of land that are connected to the mainland at one end while extending out into the water at the other.

S. Ramaseshan (1923–2017) was a prominent Indian physicist known for his contributions to the field of condensed matter physics, particularly in the areas of X-ray diffraction and crystallography. He played a significant role in the advancement of physical sciences in India and was associated with various esteemed institutions throughout his career. Ramaseshan's work included research on the structural properties of materials and the development of techniques in crystallography.

Staballoy is a type of material known primarily for its use in nuclear applications and radiation shielding. It typically consists of a tungsten alloy, which is known for its high density and ability to effectively absorb radiation. Staballoy can also be mixed with other metals, such as nickel or iron, to enhance its properties.

A stable polynomial is a concept primarily used in control theory and mathematics, particularly in the study of dynamical systems. A polynomial is defined as stable if all of its roots (or zeros) lie in the left half of the complex plane.

The standard enthalpy of reaction, often denoted as \( \Delta H^\circ \), is the change in enthalpy that occurs during a chemical reaction at standard conditions. Standard conditions typically refer to a temperature of 25 degrees Celsius (298.15 K), a pressure of 1 atmosphere (101.3 kPa), and concentrations of 1 mol/L for solutions.

The William F. Meggers Award in Spectroscopy is a prestigious award given by the Society for Applied Spectroscopy (SAS) to recognize outstanding achievements in the field of spectroscopy. Named in honor of William F. Meggers, a prominent figure in the field who made significant contributions to spectroscopic techniques, the award is intended to honor individuals who have made significant advancements and innovations in spectroscopy, whether in theory, instrumentation, or application.

William Hanson Dodge is a name that may refer to various individuals, but without additional context, it is difficult to determine which specific person you are referring to. There is no widely recognized historical figure or event specifically known by that name as of my last update in October 2023.

William Happer is an American physicist known for his work in the field of atomic physics and his research on the role of carbon dioxide in the Earth's atmosphere. He was a professor at Princeton University and has been involved in various studies related to the effects of climate change and greenhouse gases. Happer is a controversial figure in the climate change debate, often expressing skepticism about the mainstream scientific consensus on human-caused global warming.

William Marciano is a meteorologist known for his work with ABC News, where he serves as a senior meteorologist and frequently provides weather updates and analyses for various programs. He has a background in meteorology and has worked for several television stations during his career, gaining recognition for his expertise in weather forecasting.

William Morgan is a notable figure in the field of actuarial science. He is particularly recognized for his contributions to the profession, including advancements in mathematical finance and risk management. Actuaries use mathematical and statistical methods to assess risk in insurance, finance, and other industries, and Morgan may have been involved in initiatives related to education, research, or professional standards.

William R. Bennett Jr. is not a widely recognized public figure, author, or celebrity in common discourse as of my last update in October 2023. However, "William R. Bennett" could refer to individuals in various fields, including academia, business, or local politics, depending on the context. If you have a specific context or field in which you're referring to him—such as literature, science, etc.

Pinned article: Introduction to the OurBigBook Project

Welcome to the OurBigBook Project! Our goal is to create the perfect publishing platform for STEM subjects, and get university-level students to write the best free STEM tutorials ever.

Everyone is welcome to create an account and play with the site: ourbigbook.com/go/register. We belive that students themselves can write amazing tutorials, but teachers are welcome too. You can write about anything you want, it doesn't have to be STEM or even educational. Silly test content is very welcome and you won't be penalized in any way. Just keep it legal!

Intro to OurBigBook

. Source. We have two killer features:

- topics: topics group articles by different users with the same title, e.g. here is the topic for the "Fundamental Theorem of Calculus" ourbigbook.com/go/topic/fundamental-theorem-of-calculusArticles of different users are sorted by upvote within each article page. This feature is a bit like:

- a Wikipedia where each user can have their own version of each article

- a Q&A website like Stack Overflow, where multiple people can give their views on a given topic, and the best ones are sorted by upvote. Except you don't need to wait for someone to ask first, and any topic goes, no matter how narrow or broad

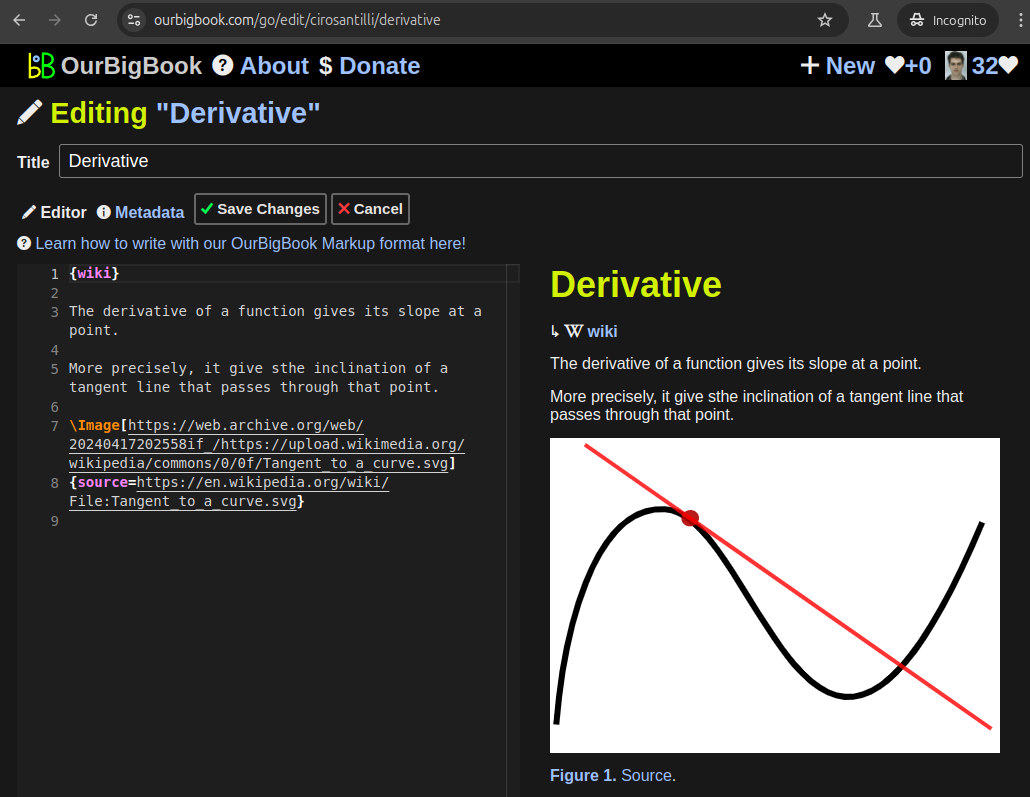

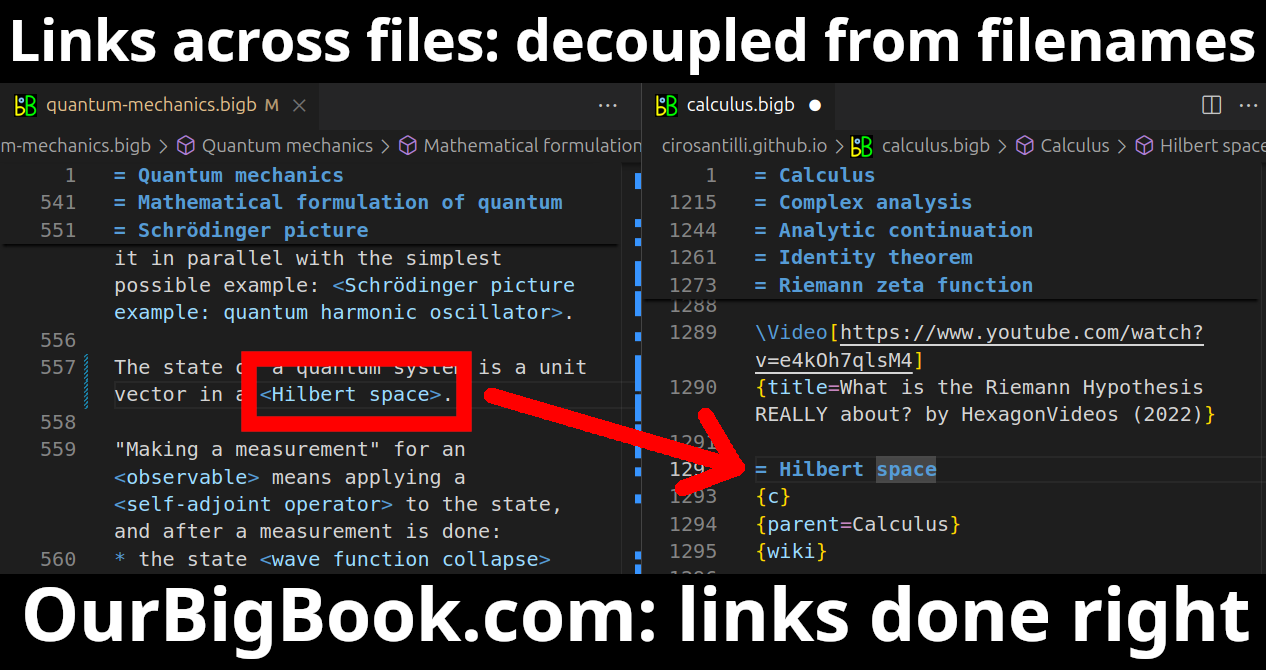

This feature makes it possible for readers to find better explanations of any topic created by other writers. And it allows writers to create an explanation in a place that readers might actually find it.Figure 1. Screenshot of the "Derivative" topic page. View it live at: ourbigbook.com/go/topic/derivativeVideo 2. OurBigBook Web topics demo. Source. - local editing: you can store all your personal knowledge base content locally in a plaintext markup format that can be edited locally and published either:This way you can be sure that even if OurBigBook.com were to go down one day (which we have no plans to do as it is quite cheap to host!), your content will still be perfectly readable as a static site.

- to OurBigBook.com to get awesome multi-user features like topics and likes

- as HTML files to a static website, which you can host yourself for free on many external providers like GitHub Pages, and remain in full control

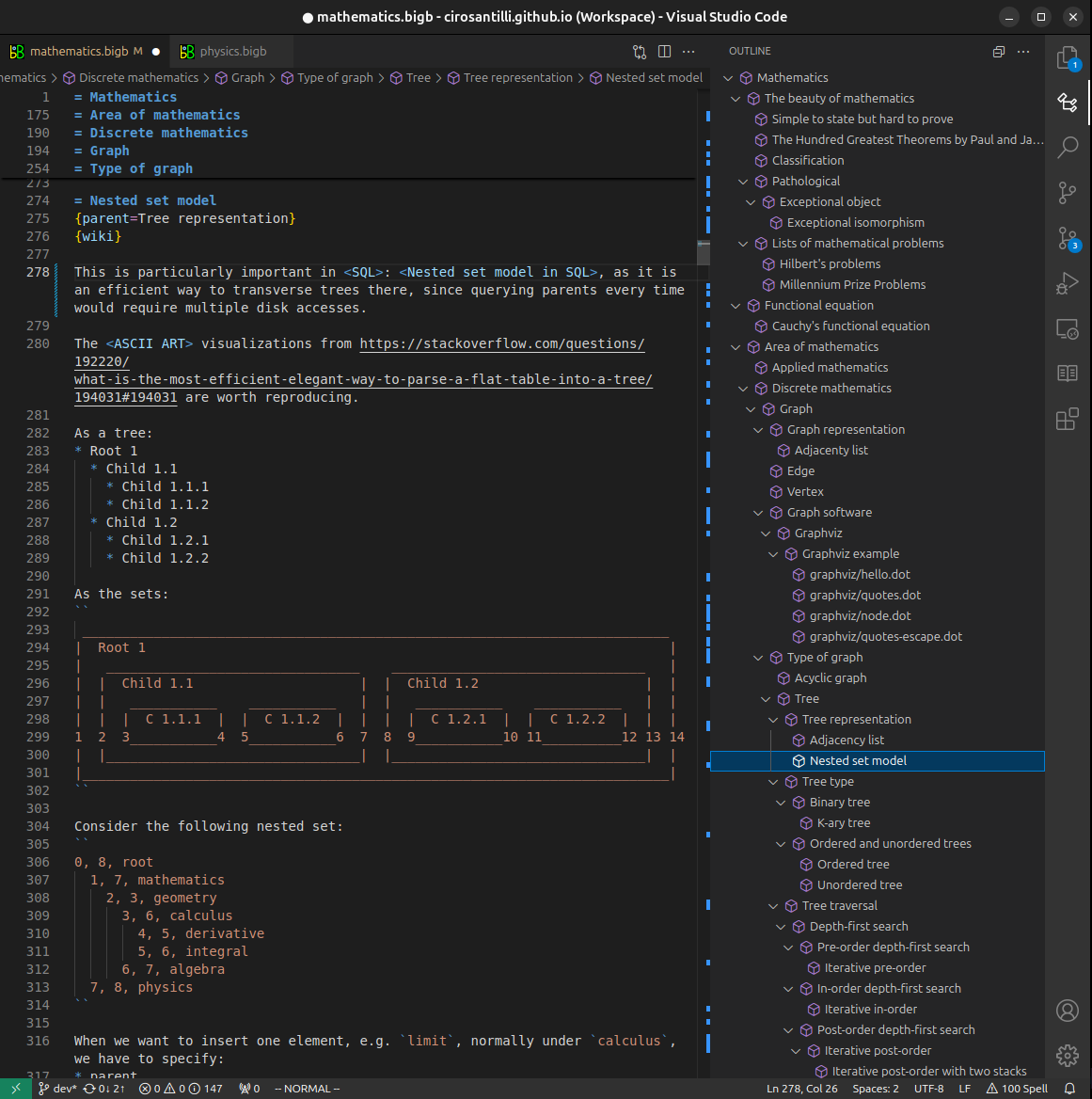

Figure 3. Visual Studio Code extension installation.Figure 4. Visual Studio Code extension tree navigation.Figure 5. Web editor. You can also edit articles on the Web editor without installing anything locally.Video 3. Edit locally and publish demo. Source. This shows editing OurBigBook Markup and publishing it using the Visual Studio Code extension.Video 4. OurBigBook Visual Studio Code extension editing and navigation demo. Source. - Infinitely deep tables of contents:

All our software is open source and hosted at: github.com/ourbigbook/ourbigbook

Further documentation can be found at: docs.ourbigbook.com

Feel free to reach our to us for any help or suggestions: docs.ourbigbook.com/#contact