The F-number, also known as the f-stop, is a numeric scale that represents the ratio of the focal length of a lens to the diameter of the aperture (the opening through which light enters the camera). It is a key factor in photography and optics that affects the exposure and depth of field of an image.

The Lockhart–Martinelli parameter (often denoted as \( X \)) is a dimensionless number used in the field of two-phase flow, particularly in the study of boiling and condensation processes. It is commonly applied in the analysis of pressure drop in pipelines carrying both liquid and vapor phases.

The Sherwood number (Sh) is a dimensionless number used in mass transfer operations to characterize the mass transfer processes, particularly in convective mass transfer. It is analogous to the Nusselt number in heat transfer.

A Directed Acyclic Graph (DAG) is a type of graph that has two main characteristics: 1. **Directed**: This means that the edges (connections) between the nodes (vertices) have a direction. In other words, if there is a directed edge from node A to node B, this implies a one-way relationship, indicating that A influences B, or A precedes B in some context.

A Kautz graph is a type of directed graph that is used in combinatorial design and graph theory. It is defined by a specific set of parameters that determine its structure. The Kautz graph \( K(n, k) \) is constructed using two parameters: \( n \) and \( k \).

The term "vertex-symmetric digraphs" typically refers to directed graphs (digraphs) that exhibit a certain level of symmetry with respect to their vertices. In general, a directed graph consists of vertices and directed edges (arcs) connecting them, and a vertex-symmetric digraph is one that behaves the same way when vertices are permuted.

In graph theory, a **tournament** is a special type of directed graph (digraph) that represents the outcomes of pairwise competitions among a set of participants. Specifically, a tournament consists of a finite set of vertices, where each vertex represents a participant, and for every pair of distinct vertices \(u\) and \(v\), there is exactly one directed edge.

Discontinued Microsoft software refers to applications, services, or operating systems that Microsoft has officially stopped supporting, selling, or developing. Over the years, Microsoft has released numerous products, many of which have been phased out as technology advances or business priorities change. Here are some notable examples: 1. **Windows XP**: Widely used for many years, Windows XP reached the end of its support lifecycle in April 2014. Microsoft no longer provides security updates or technical support for this operating system.

AOLpress is a WYSIWYG (What You See Is What You Get) HTML editor that was developed by AOL (America Online) in the late 1990s. It was designed to allow users to create and edit web pages easily without needing to understand the underlying HTML code. AOLpress included features like page layout tools, support for basic HTML elements, and the ability to publish directly to web servers.

As of my last knowledge update in October 2023, "CA-Cricket Presents" is not a widely recognized term or brand. It could refer to a variety of cricket-related events, promotions, or content initiatives by Cricket Australia or a cricket-related organization.

Discontinued development tools refer to programming tools, libraries, frameworks, or software development environments that are no longer actively developed or maintained by their creators. This might mean that the developers have stopped releasing updates, bug fixes, or new features, and the tool is effectively considered obsolete. Discontinuation can occur for various reasons, including: 1. **Shift in Technology Trends**: New languages, frameworks, or paradigms may emerge, making older tools less relevant.

Discontinued operating systems are software programs that manage computer hardware and software resources but are no longer supported, maintained, or developed by their respective creators. Once an operating system (OS) has reached its end of life (EOL), it typically does not receive updates, security patches, or technical support. This can happen for several reasons, including: 1. **Market Changes:** Changes in technology or consumer preferences may lead companies to focus on newer products.

20/20 is a cloud-based spreadsheet software designed for ease of use, particularly for teams and businesses. It typically combines the functionality of traditional spreadsheets with collaborative features, allowing multiple users to work on a document simultaneously. The software often includes functionalities such as real-time editing, version control, and integration with other tools and applications. The name "20/20" usually signifies clarity and vision, implying that the software aims to provide a clear and efficient way to analyze data.

AskSam is a software application designed for managing and organizing information. Originally developed in the 1990s, it serves as a personal database tool that allows users to create, store, and retrieve various types of information such as text, documents, contacts, and other data. AskSam is known for its ability to import and search large amounts of data efficiently, making it suitable for researchers, writers, and professionals who need to organize extensive information.

Autodesk Softimage was a 3D computer graphics program used for animation, modeling, visual effects, and rendering. Originally developed by Softimage, Inc., it gained popularity in the film, television, and video game industries for its powerful animation and character rigging tools. Softimage was particularly well-regarded for its advanced tools for character animation, including the use of a non-linear animation system and enhanced simulation capabilities.

Connotea was a social bookmarking service designed specifically for researchers and academics. Launched in 2004, it allowed users to store, organize, and share scholarly articles and references. Users could tag articles, create bibliographies, and discover content shared by others in the research community. The platform aimed to facilitate collaboration and knowledge sharing among researchers by making it easier to manage and access scientific literature.

Cricket Paint, also known as "Cricket Paint Co," is a brand that specializes in a variety of paints and coatings for different applications. While not necessarily exclusive to cricket (the sport), it may have products that cater to cricket nets, pitches, or other sports surfaces.

Norton SystemWorks is a suite of utility software developed by Symantec (now part of Broadcom Inc.) that is designed to optimize the performance and maintenance of personal computers. The software package includes various tools for managing and repairing computer systems, ensuring data security, and improving overall efficiency. Key features often include: 1. **Disk Optimization**: Tools for defragmenting hard drives and optimizing disk space.

Firestarter is an open-source firewall application for Linux systems that provides a graphical user interface (GUI) for managing firewall rules and settings. It is particularly designed for use with the iptables firewall, which is the default firewall utility in many Linux distributions. Key features of Firestarter include: 1. **User-friendly Interface:** Firestarter provides an easy-to-navigate GUI that simplifies the process of configuring firewall rules, making it accessible even for users who may not be familiar with command-line tools.

GIFBuilder is a tool or software that allows users to create GIF (Graphics Interchange Format) animations. These tools often let users combine a series of images or video clips into a single animated GIF file, adjust parameters like frame duration, and apply effects or filters. GIFBuilders can be found as standalone applications or integrated into various online platforms. They typically offer features such as: 1. **Image Upload**: Users can upload images from their device or use images from the web.

Pinned article: Introduction to the OurBigBook Project

Welcome to the OurBigBook Project! Our goal is to create the perfect publishing platform for STEM subjects, and get university-level students to write the best free STEM tutorials ever.

Everyone is welcome to create an account and play with the site: ourbigbook.com/go/register. We belive that students themselves can write amazing tutorials, but teachers are welcome too. You can write about anything you want, it doesn't have to be STEM or even educational. Silly test content is very welcome and you won't be penalized in any way. Just keep it legal!

Intro to OurBigBook

. Source. We have two killer features:

- topics: topics group articles by different users with the same title, e.g. here is the topic for the "Fundamental Theorem of Calculus" ourbigbook.com/go/topic/fundamental-theorem-of-calculusArticles of different users are sorted by upvote within each article page. This feature is a bit like:

- a Wikipedia where each user can have their own version of each article

- a Q&A website like Stack Overflow, where multiple people can give their views on a given topic, and the best ones are sorted by upvote. Except you don't need to wait for someone to ask first, and any topic goes, no matter how narrow or broad

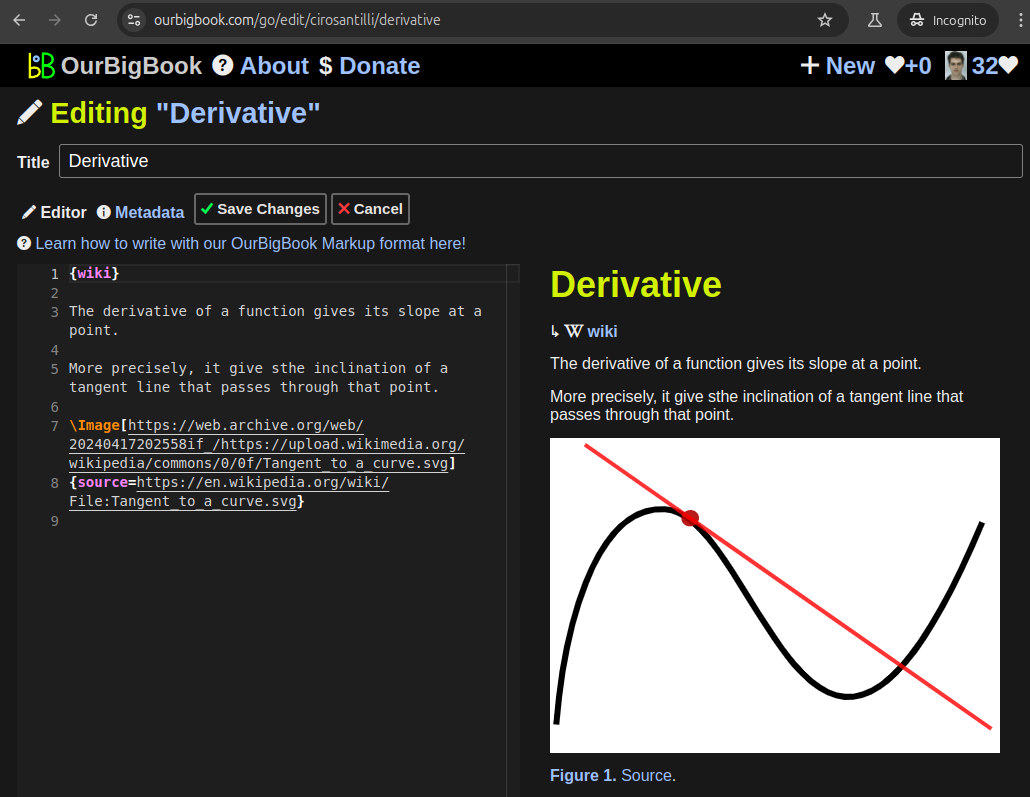

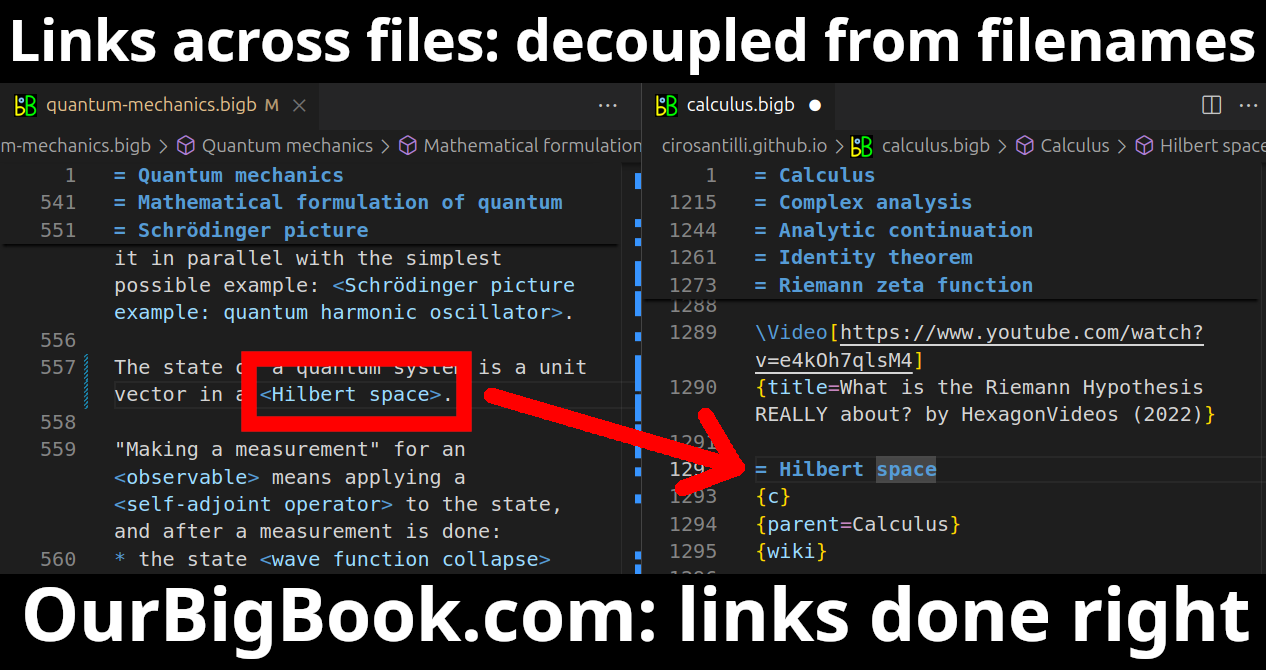

This feature makes it possible for readers to find better explanations of any topic created by other writers. And it allows writers to create an explanation in a place that readers might actually find it.Figure 1. Screenshot of the "Derivative" topic page. View it live at: ourbigbook.com/go/topic/derivativeVideo 2. OurBigBook Web topics demo. Source. - local editing: you can store all your personal knowledge base content locally in a plaintext markup format that can be edited locally and published either:This way you can be sure that even if OurBigBook.com were to go down one day (which we have no plans to do as it is quite cheap to host!), your content will still be perfectly readable as a static site.

- to OurBigBook.com to get awesome multi-user features like topics and likes

- as HTML files to a static website, which you can host yourself for free on many external providers like GitHub Pages, and remain in full control

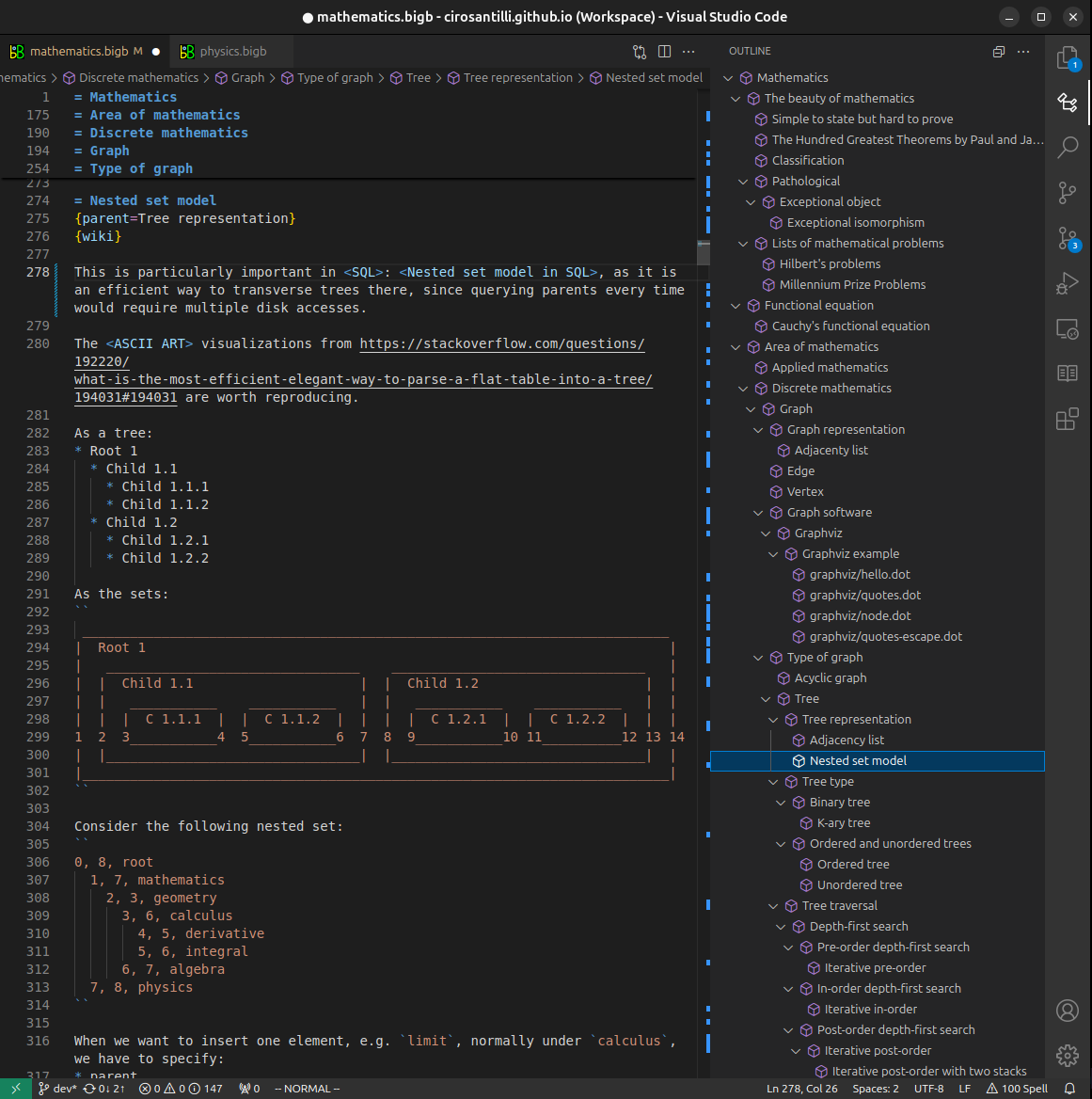

Figure 3. Visual Studio Code extension installation.Figure 4. Visual Studio Code extension tree navigation.Figure 5. Web editor. You can also edit articles on the Web editor without installing anything locally.Video 3. Edit locally and publish demo. Source. This shows editing OurBigBook Markup and publishing it using the Visual Studio Code extension.Video 4. OurBigBook Visual Studio Code extension editing and navigation demo. Source. - Infinitely deep tables of contents:

All our software is open source and hosted at: github.com/ourbigbook/ourbigbook

Further documentation can be found at: docs.ourbigbook.com

Feel free to reach our to us for any help or suggestions: docs.ourbigbook.com/#contact