"Four Epigraphs after Escher" is a composition for solo piano by the American composer and pianist *Ned Rorem*. Written in 1998, the piece is inspired by the works of the Dutch graphic artist M.C. Escher, known for his mathematically inspired artwork that explores patterns, symmetry, and impossible constructions.

In materials science, **polymorphism** refers to the ability of a material to exist in two or more different forms or crystal structures. These different forms can have distinct physical and chemical properties, which can affect the material's behavior in applications. Polymorphism is especially significant in the context of materials like metals, minerals, and polymers. For example: 1. **Metals**: Some metals can adopt different crystal structures depending on temperature or other conditions.

"Mott the Hoople" is the self-titled debut album by the British rock band Mott the Hoople, released in 1969. The band, formed in 1969 in Herefordshire, England, was known for its eclectic style and became an influential group in the glam rock movement. The album features a blend of rock, pop, and other musical influences, showcasing the band's early sound.

"Clocks" can refer to different concepts depending on the context. Here are a few possibilities: 1. **Timekeeping Devices**: Clocks are instruments used to measure and indicate time. They can be mechanical, electronic, or digital, and are found in various forms, including wall clocks, wristwatches, alarm clocks, and more.

Cutting machines are devices designed to cut various materials into specific shapes, sizes, or profiles. They are used in a variety of industries, including manufacturing, construction, textiles, and more. The types of cutting machines can vary widely depending on the materials they are intended to cut and the complexity of the cutting process. Here are some common types of cutting machines: 1. **Laser Cutting Machines**: Utilize a high-powered laser to cut through materials like metal, wood, plastic, and fabric.

Machinery refers to a system of machines, or components that work together to perform a specific function or achieve a desired outcome. It typically encompasses various mechanical devices that can include things like engines, tools, equipment, and other instruments. Machinery can be powered manually, electrically, or through other energy sources such as hydraulics or pneumatics.

Positive vorticity advection refers to the process in meteorology where air with higher vorticity (a measure of the local rotation in the flow of air) is transported into a region with lower vorticity. Vorticity is associated with the circulation of air, and positive vorticity is when there is a counterclockwise rotation in the Northern Hemisphere (and clockwise in the Southern Hemisphere, due to the Coriolis effect).

Simple machines are basic mechanical devices that change the direction or magnitude of a force. They are foundational components in the study of mechanics and physics. There are six classical types of simple machines, each with its specific function: 1. **Lever**: A rigid bar that rotates around a fixed point called the fulcrum. Levers can amplify force or change the direction of the force, making it easier to lift or move objects.

"Graphotype" typically refers to a type of machine used for creating typesetting and printing. Originally developed in the late 19th century, Graphotype machines were used for composing and casting types for printing presses. They allowed for the rapid production of metal type characters that could be used to print text and images, significantly streamlining the typesetting process in the printing industry.

In physics, collisions are typically classified into two main types: elastic and inelastic collisions. The primary difference between the two lies in the conservation of kinetic energy during the collision process. ### Elastic Collisions In an elastic collision: 1. **Conservation of Momentum**: The total momentum of the system is conserved before and after the collision. 2. **Conservation of Kinetic Energy**: The total kinetic energy of the system is also conserved before and after the collision.

A roof seamer is a specialized tool or machine used in the roofing industry, primarily for metal roofing applications. Its main function is to create seams between metal panels, ensuring that they are tightly sealed and securely connected. This helps in preventing leaks and enhancing the durability and longevity of the roof. There are different types of roof seamers: 1. **Manual Roof Seamers**: These are handheld tools that allow roofing professionals to crimp and seal seams manually. They typically require physical effort to operate.

Bismuth-indium refers to an alloy primarily composed of bismuth (Bi) and indium (In). Both of these metals have low melting points compared to other metals, which make their alloys useful in various applications. Bismuth itself has a melting point of about 271.4 °C (520.5 °F), while indium melts at around 156.6 °C (313.9 °F).

Mechanophilia is a form of paraphilia characterized by a sexual attraction to machines or mechanical objects. This attraction can manifest in various forms, including feelings of arousal from interacting with or imagining sexual acts involving machines, vehicles, or mechanical devices. Like other paraphilias, mechanophilia can vary in intensity and may be a significant aspect of an individual's sexual identity for some people. It is a topic that intersects with psychology, sexuality, and sometimes even art and culture.

A rotary union, also known as a rotary joint or swivel joint, is a mechanical device that allows the transmission of fluid (liquid or gas) from a stationary source to a rotating component. This technology is commonly used in applications where pipes or hoses must remain connected while one end rotates, such as in machinery, robotics, and industrial systems. The functioning of a rotary union involves seals and bearings that enable fluid flow through the stationary and rotating parts while minimizing leakage and wear.

A tunnel washer is a type of industrial washing machine used primarily for cleaning textiles, such as towels, linens, and garments, in large-scale laundry operations. The design of a tunnel washer allows for a continuous, efficient washing process, where items move through a series of compartments or stages, each with specific functions for washing, rinsing, and drying.

The 't Hooft loop is a concept from theoretical physics, particularly in the context of gauge theories, including quantum field theories and string theories. It is named after the physicist Gerard 't Hooft, who made significant contributions to our understanding of gauge theories. In a gauge theory, the 't Hooft loop is an operator that creates a magnetic monopole-like configuration or represents the dual description of certain non-abelian gauge theories.

Zigbee is a wireless communication protocol designed for short-range communication and low-power consumption, primarily used in the Internet of Things (IoT) for applications such as home automation, industrial control, and smart energy. It is based on the IEEE 802.15.4 standard and operates in the 2.4 GHz, 915 MHz, and 868 MHz frequency bands.

The Electromagnetic Aircraft Launch System (EMALS) is a technology used to launch aircraft from an aircraft carrier using electromagnetic forces rather than traditional steam catapults. EMALS was developed primarily by the U.S. Navy as part of its efforts to modernize naval aviation capabilities. ### Key Features of EMALS: 1. **Electromagnetic Propulsion**: EMALS uses linear motors, specifically linear induction motors, to accelerate aircraft along a launch track.

Cubane is a hydrocarbon with the chemical formula C₈H₈. It is a type of saturated cyclic compound, specifically an eight-membered carbon ring, consisting of eight carbon atoms linked in a square planar arrangement with hydrogen atoms attached. Its structure is notable because it resembles a cube, which is where it gets its name. Cubane is of interest in the field of chemistry due to its unique structure and properties.

The term "dual photon" can refer to a few different concepts depending on the context in which it's used. Here are some possible interpretations: 1. **In Particle Physics**: "Dual photon" might refer to interactions or phenomena involving two photons, such as in the context of quantum electrodynamics (QED) or in experimental setups where photon-photon interactions are studied.

Pinned article: Introduction to the OurBigBook Project

Welcome to the OurBigBook Project! Our goal is to create the perfect publishing platform for STEM subjects, and get university-level students to write the best free STEM tutorials ever.

Everyone is welcome to create an account and play with the site: ourbigbook.com/go/register. We belive that students themselves can write amazing tutorials, but teachers are welcome too. You can write about anything you want, it doesn't have to be STEM or even educational. Silly test content is very welcome and you won't be penalized in any way. Just keep it legal!

Intro to OurBigBook

. Source. We have two killer features:

- topics: topics group articles by different users with the same title, e.g. here is the topic for the "Fundamental Theorem of Calculus" ourbigbook.com/go/topic/fundamental-theorem-of-calculusArticles of different users are sorted by upvote within each article page. This feature is a bit like:

- a Wikipedia where each user can have their own version of each article

- a Q&A website like Stack Overflow, where multiple people can give their views on a given topic, and the best ones are sorted by upvote. Except you don't need to wait for someone to ask first, and any topic goes, no matter how narrow or broad

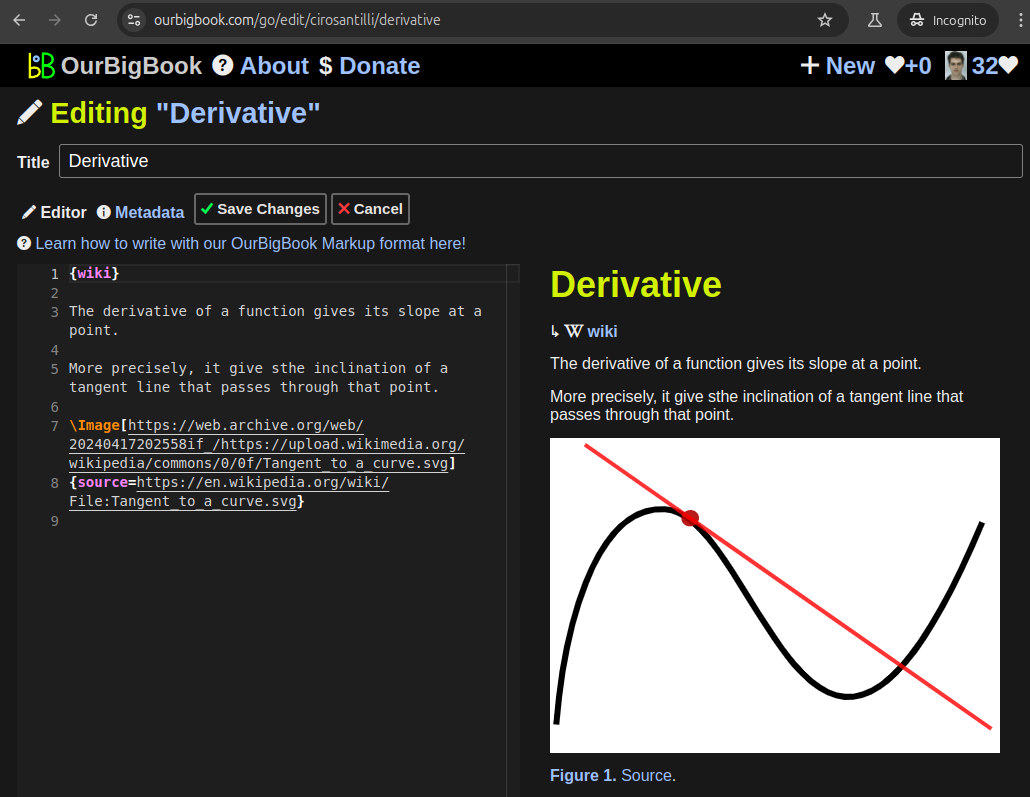

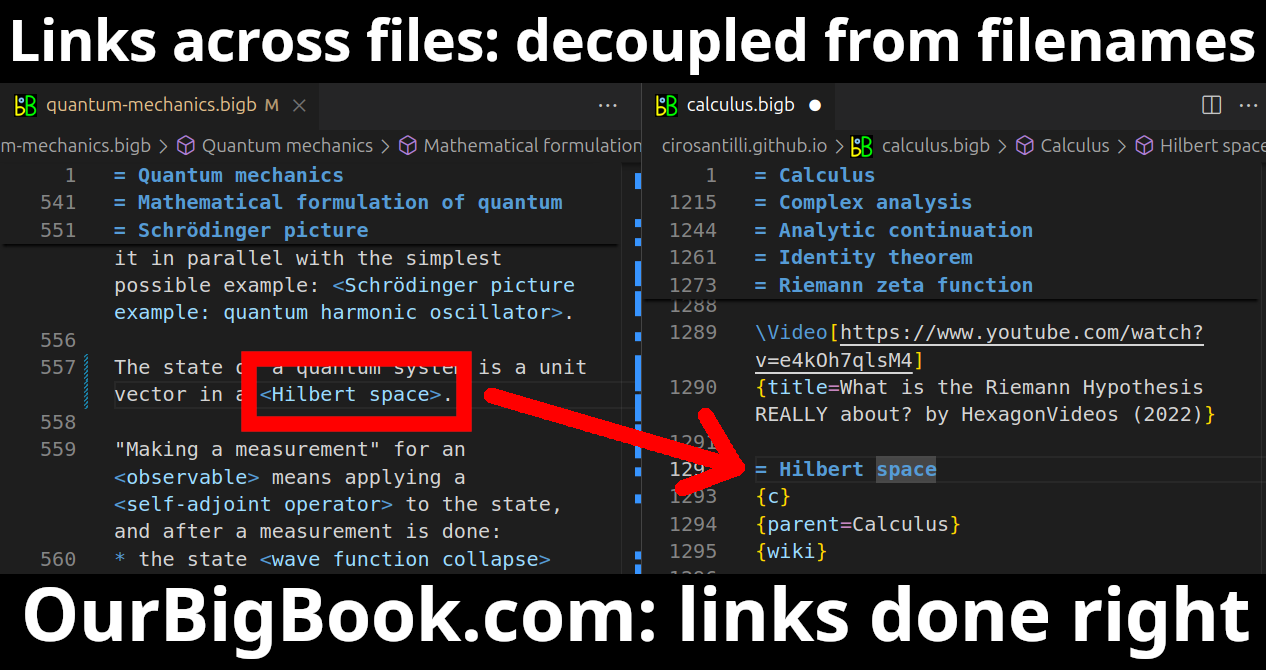

This feature makes it possible for readers to find better explanations of any topic created by other writers. And it allows writers to create an explanation in a place that readers might actually find it.Figure 1. Screenshot of the "Derivative" topic page. View it live at: ourbigbook.com/go/topic/derivativeVideo 2. OurBigBook Web topics demo. Source. - local editing: you can store all your personal knowledge base content locally in a plaintext markup format that can be edited locally and published either:This way you can be sure that even if OurBigBook.com were to go down one day (which we have no plans to do as it is quite cheap to host!), your content will still be perfectly readable as a static site.

- to OurBigBook.com to get awesome multi-user features like topics and likes

- as HTML files to a static website, which you can host yourself for free on many external providers like GitHub Pages, and remain in full control

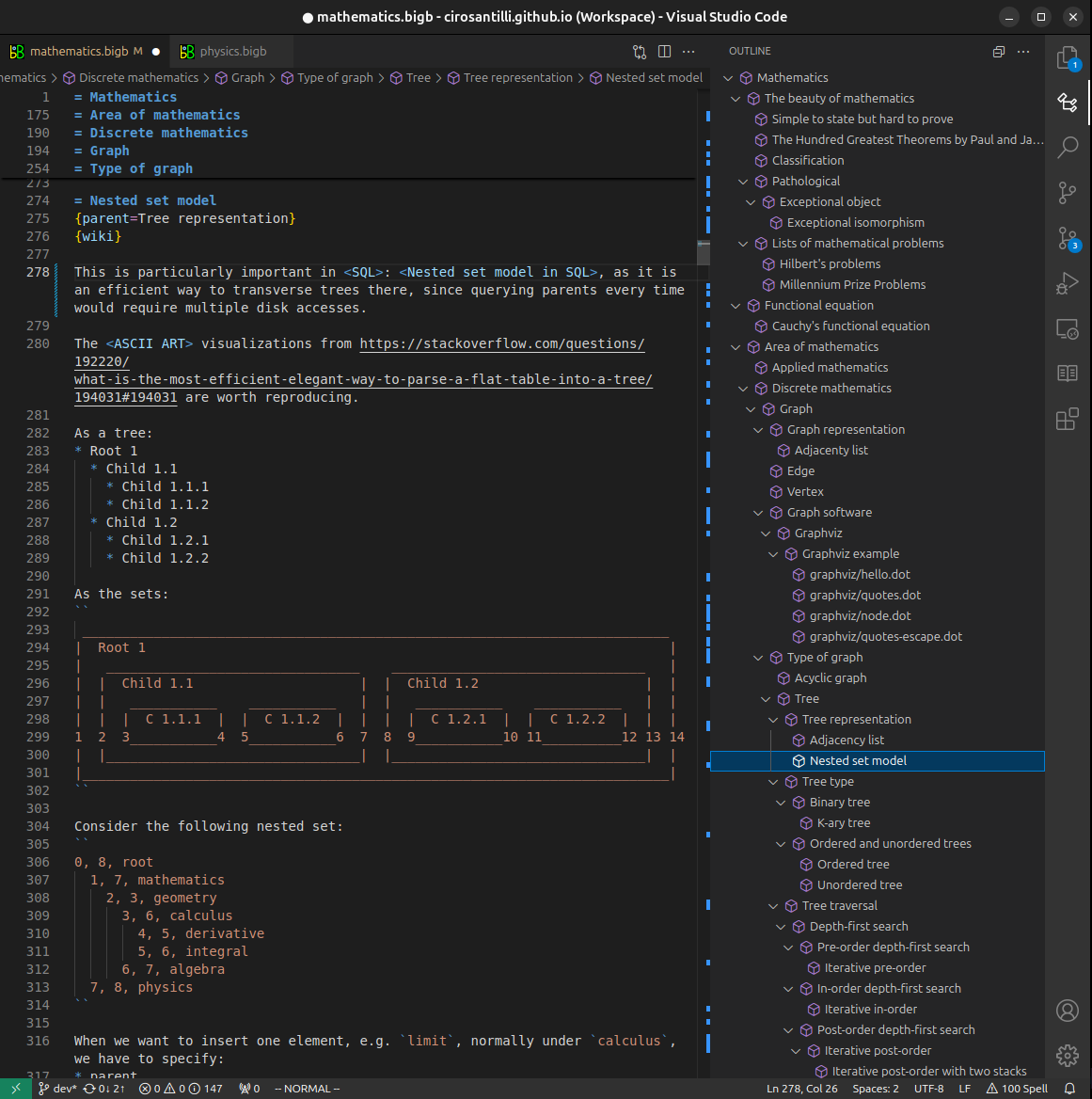

Figure 3. Visual Studio Code extension installation.Figure 4. Visual Studio Code extension tree navigation.Figure 5. Web editor. You can also edit articles on the Web editor without installing anything locally.Video 3. Edit locally and publish demo. Source. This shows editing OurBigBook Markup and publishing it using the Visual Studio Code extension.Video 4. OurBigBook Visual Studio Code extension editing and navigation demo. Source. - Infinitely deep tables of contents:

All our software is open source and hosted at: github.com/ourbigbook/ourbigbook

Further documentation can be found at: docs.ourbigbook.com

Feel free to reach our to us for any help or suggestions: docs.ourbigbook.com/#contact